ʻO kāu koho wili maikaʻi loa

E nānā i nā ʻano huahana

3.4k

HUI HANA

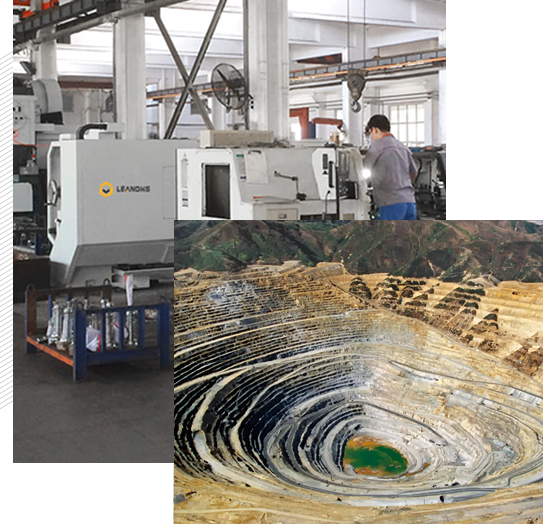

Hoʻonohonoho ka ʻenekinia a me ka ʻenehana i nā mea kūpono no ka pilikia abrasion.

25+

R&K

Hoʻomau mākou i ka hoʻomaikaʻi ʻana i kā mākou ʻōnaehana e hōʻoia i ka maikaʻi paʻa o nā mea o kēia manawa a hōʻike i ka composite hou e kūpono i ka pilikia abrasion hou.

18+

LOA KA HANA HANA

7x24h kākoʻo ʻenehana a lawe mākou i ke kuleana 100% i kā mākou pilikia

5.9%

Lawelawe mea kūʻai mai

Hoʻopili ka hui ʻenehana & ʻoihana i kēlā me kēia noi ma ke kūkākūkā a i ʻole nā laʻana a i ʻole nā mea hoʻouna.

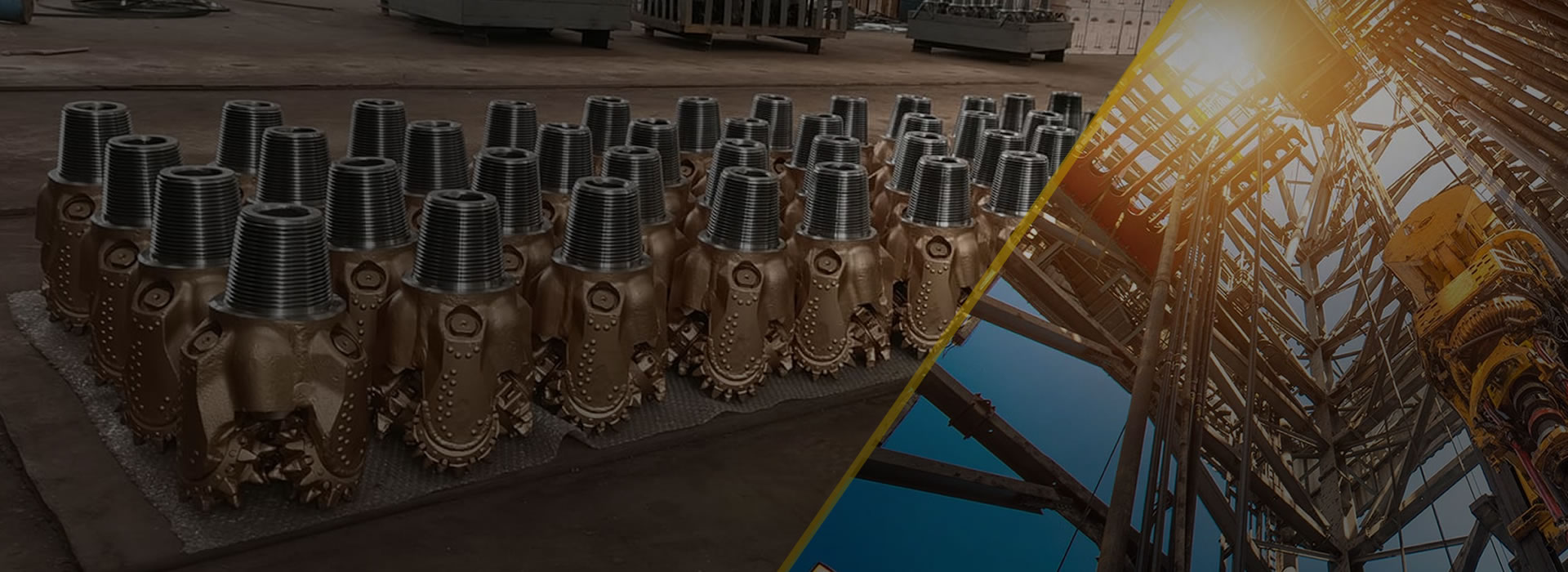

Hāʻawi mākou i nā mea hana wili lōʻihi

lawelawe ʻoihana

lawelawe ʻoihana

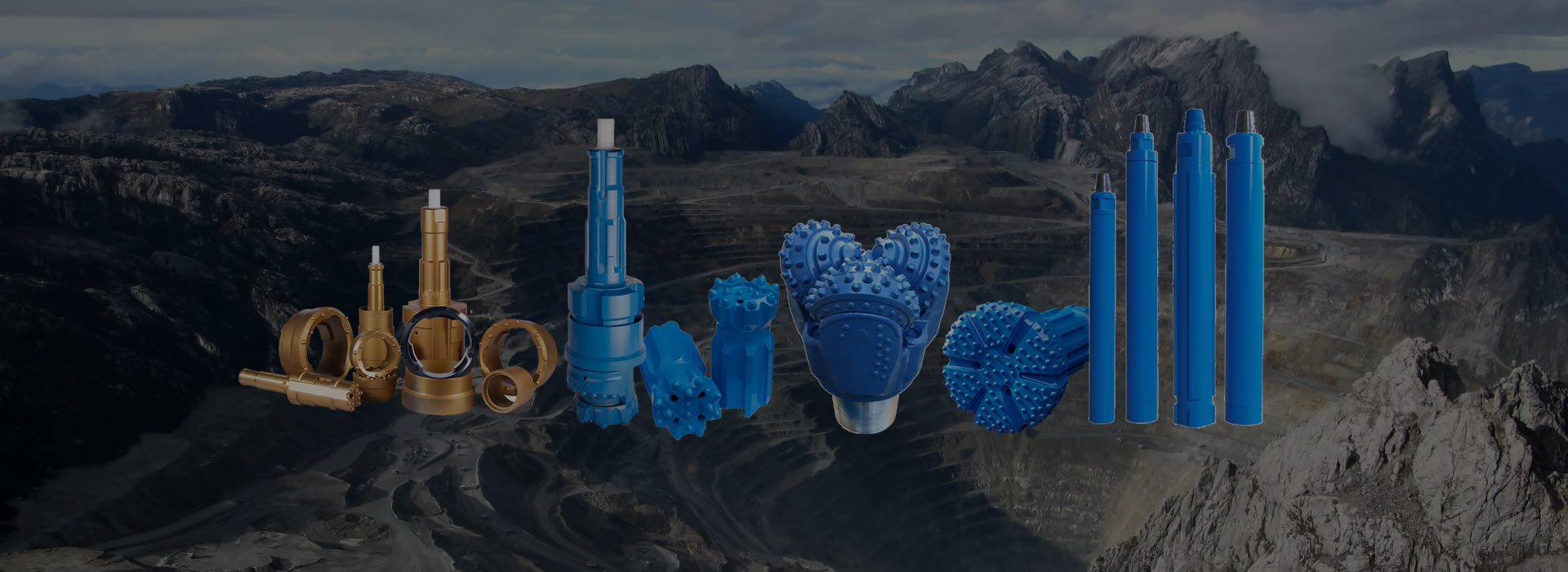

Ua lawelawe ʻo DrillMore Rock Tools Company i ka ʻoihana wili no nā makahiki he 30. He loea mākou i ka hoʻolālā, hoʻomohala, hana, a me ka lawelawe ʻana i nā tricone bits, DTH tools, Top Hammer Tools, PDC Bits for Mining, Well drilling, Geothermal drilling, Construction, Tunneling, Quarrying...

- Mea hoolako oihana

No ka Hana HanaHana Kūʻai Kūikawā - Hoʻolālā Kūlana Kiʻekiʻe

Ka Mana Ko'iko'iE noʻonoʻo i ka Competitive

Nā Nūhou Hou a me nā mea hou