Chaguo lako Bora la Kuchimba Visima

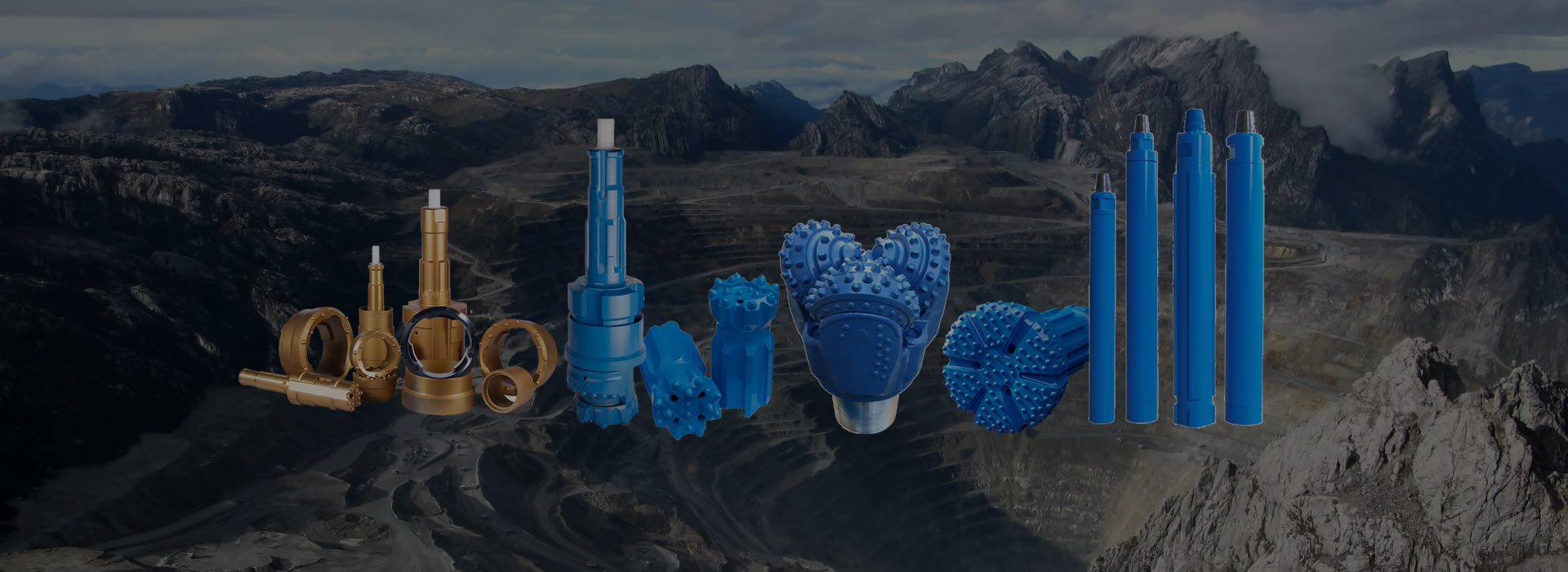

Vinjari Aina za Bidhaa

3.4k

TIMU YA WATAALAM

Mhandisi na fundi hupanga nyenzo sahihi kwa shida ya abrasion.

25+

R&D

Tunaendelea kuboresha mfumo wetu kuhakikisha ubora thabiti wa nyenzo za sasa na kupendekeza muundo mpya ili kutoshea tatizo jipya la mikwaruzo.

18+

KWENYE HUDUMA YA TOVUTI INAPATIKANA

Usaidizi wa kiufundi wa saa 7x24 na tunawajibikia 100% tatizo letu

5.9%

Huduma kwa wateja

Timu ya kiufundi na kibiashara hufuatilia kila ombi la mshauri au sampuli au usafirishaji.

Tunatoa Zana za Kuchimba Visima za Kudumu

Huduma ya Kitaalamu

Huduma ya Kitaalamu

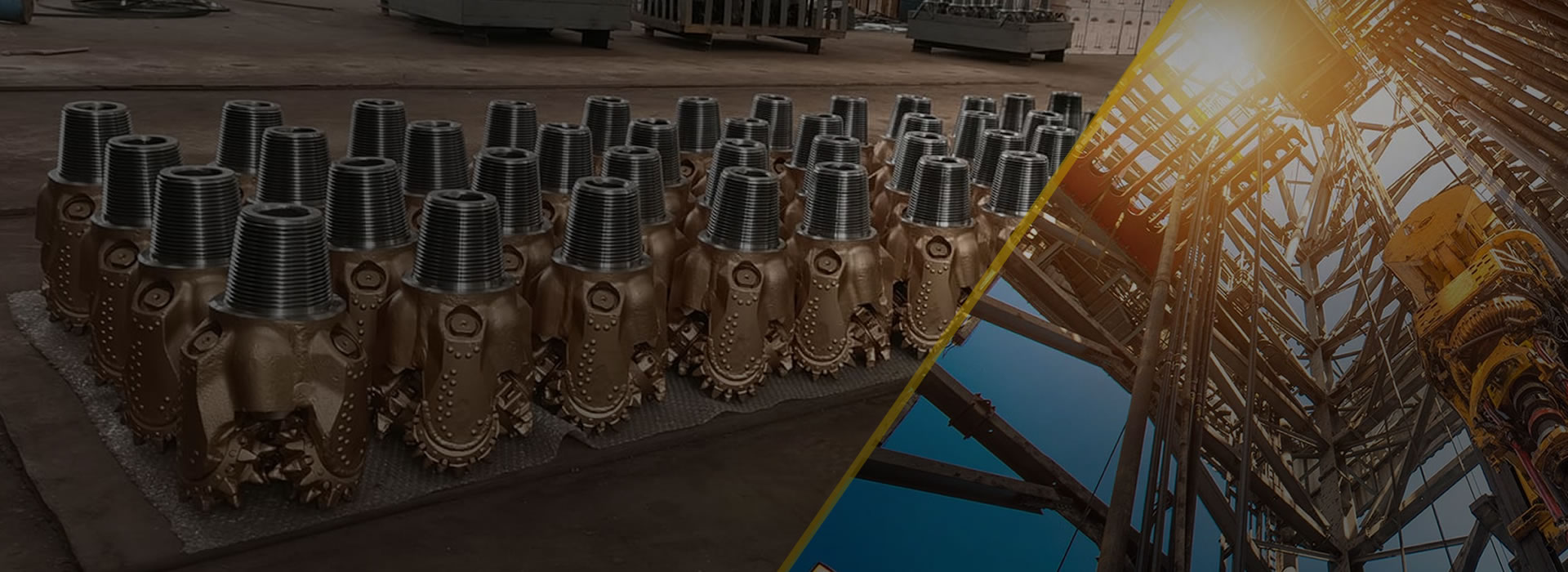

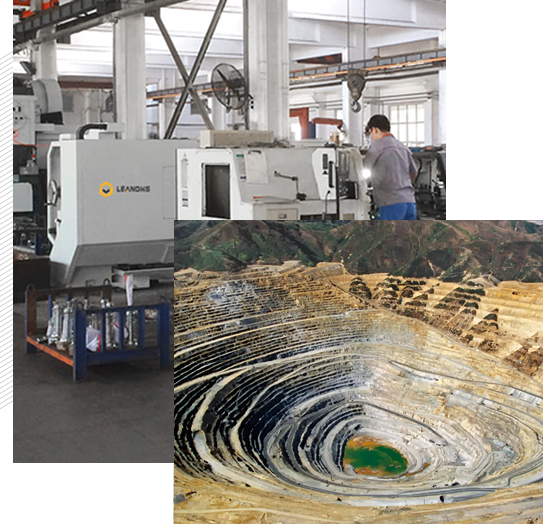

Kampuni ya DrillMore Rock Tools imetumikia tasnia ya uchimbaji visima kwa zaidi ya miaka 30. Tunabobea katika uundaji, uundaji, utengenezaji na huduma ya biti za tricone, zana za DTH, Zana za Juu za Nyundo, Biti za PDC za Uchimbaji Madini, Uchimbaji wa Visima, Uchimbaji wa Jotoardhi, Ujenzi, Uchimbaji Mifereji, Uchimbaji mawe...

- Msambazaji Mtaalamu

Kwa Viwanda vya Kuchimba VisimaHuduma ya Kipekee kwa Wateja - Ubunifu wa Ubora wa Juu

Udhibiti Mkali wa UboraZingatia Ushindani

Habari na Taarifa za Hivi Punde