Pilihan Drilling Panjenengan Best

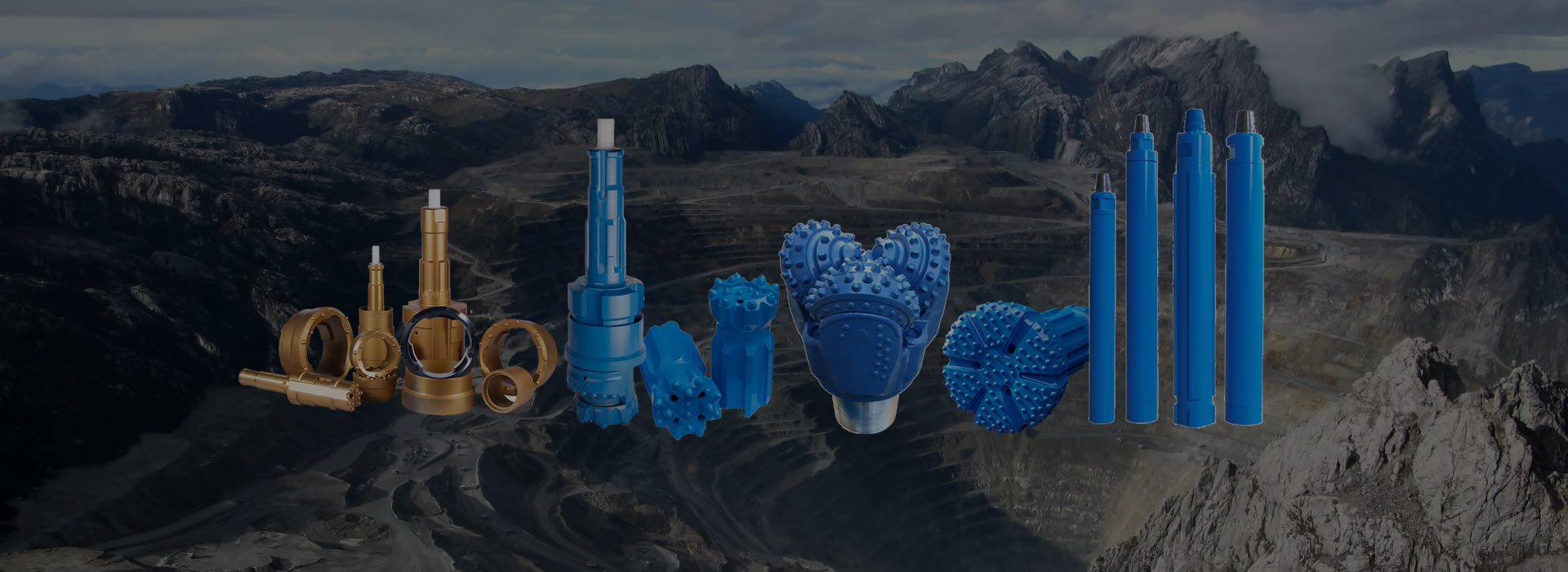

Telusuri Kategori Produk

3.4k

TIM PROFESIONAL

Insinyur lan teknisi ngatur bahan sing bener kanggo masalah abrasi.

25+

R&D

Kita terus nambah sistem kita nggawe manawa kualitas stabil saka bahan saiki lan suggest komposit anyar pas masalah abrasion anyar.

18+

ON SITE SERVICE kasedhiya

Dhukungan teknis 7x24h lan kita tanggung jawab 100% babagan masalah kita

5.9%

layanan pelanggan

Tim teknis & komersial tindakake saben panjalukan ing konsultan utawa conto utawa kiriman.

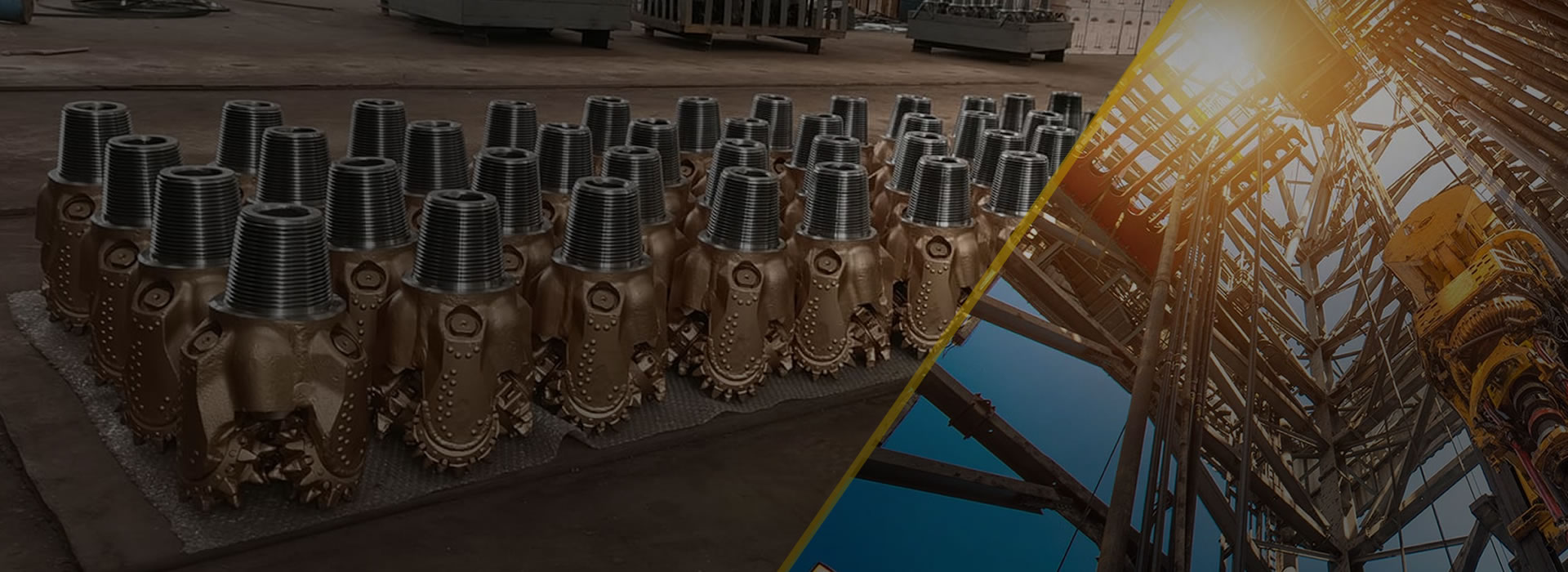

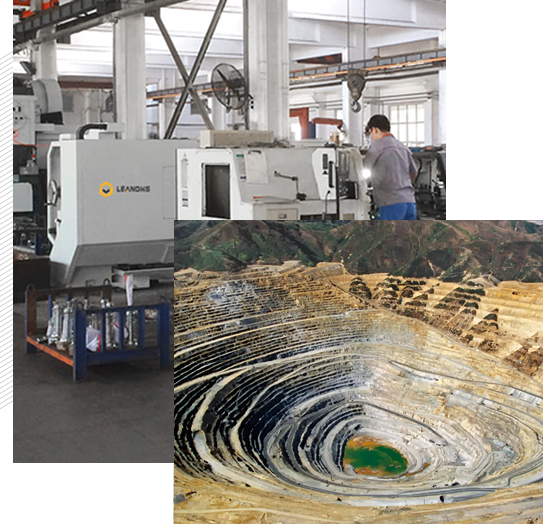

Kita Nawakake Alat Pengeboran Awet

Layanan Profesional

Layanan Profesional

DrillMore Rock Tools Company wis nglayani industri pengeboran luwih saka 30 taun. Kami spesialis ing desain, pangembangan, manufaktur, lan layanan bit tricone, alat DTH, Alat Top Hammer, Bit PDC kanggo Pertambangan, Pengeboran Sumur, Pengeboran Panas Bumi, Konstruksi, Terowongan, Penggalian...

- Supplier profesional

Kanggo Industri PengeboranLayanan Pelanggan sing luar biasa - Desain Kualitas Tinggi

Kontrol kualitas sing ketatKonsentrasi ing Kompetitif

Warta & Nganyari Paling Anyar