Jo bêste Drilling Choice

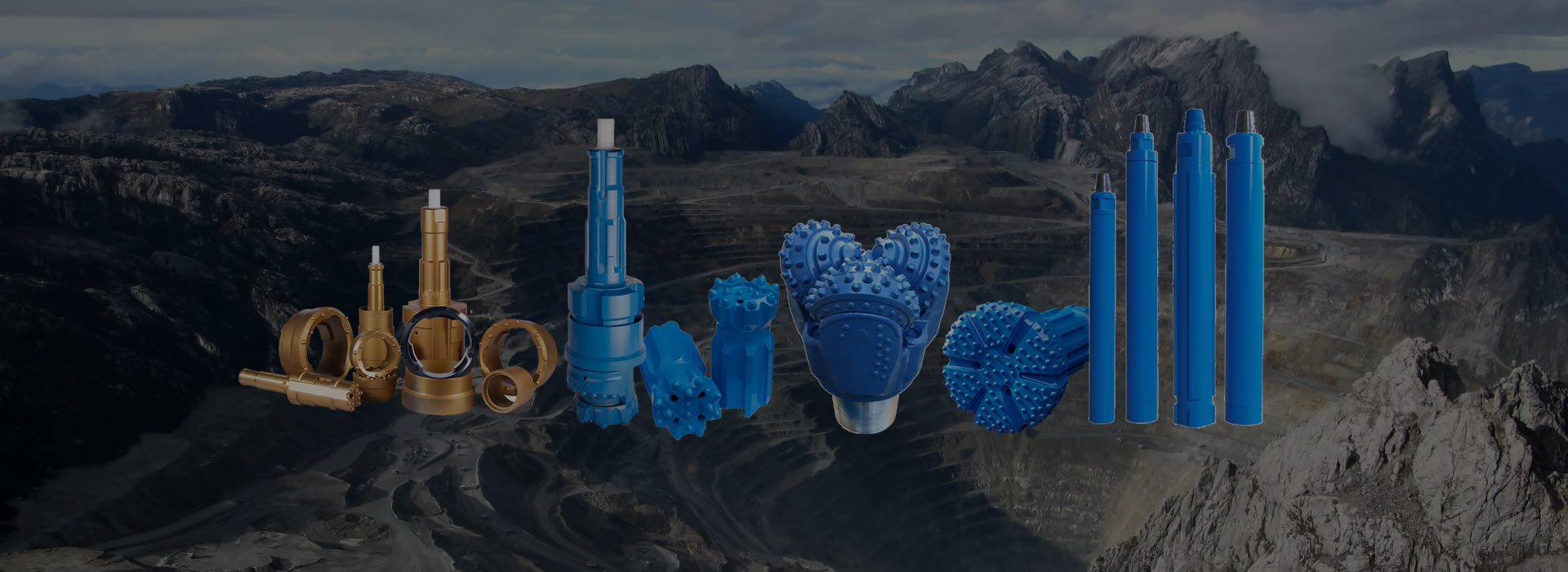

Browse Products Kategoryen

3.4k

PROFESJONEEL TEAM

Yngenieur en technikus organisearje juste materialen foar abrasionsprobleem.

25+

R&D

Wy bliuwend ferbetterje ús systeem soargje foar stabile kwaliteit fan hjoeddeistige materialen en suggerearje nije gearstalling te passen nij abrasion probleem.

18+

ON SITE SERVICE BESKIKBAAR

7x24h technyske stipe en wy nimme 100% ferantwurdlikens op ús probleem

5.9%

Klantentsjinst

Technysk en kommersjeel team folgje elke oanfraach op oer adviseur as samples as ferstjoerings.

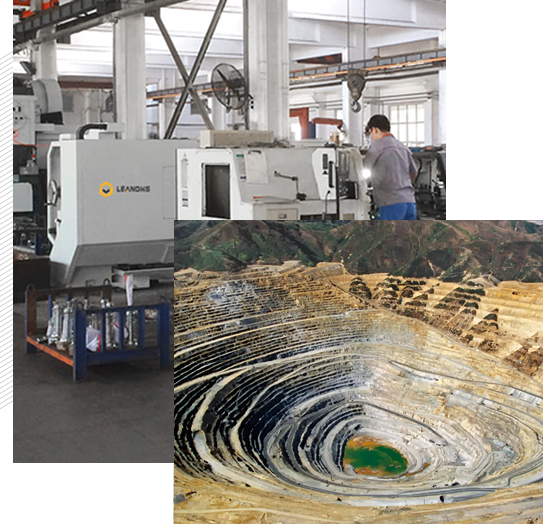

Wy biede duorsum drilling ark

Profesjonele tsjinst

Profesjonele tsjinst

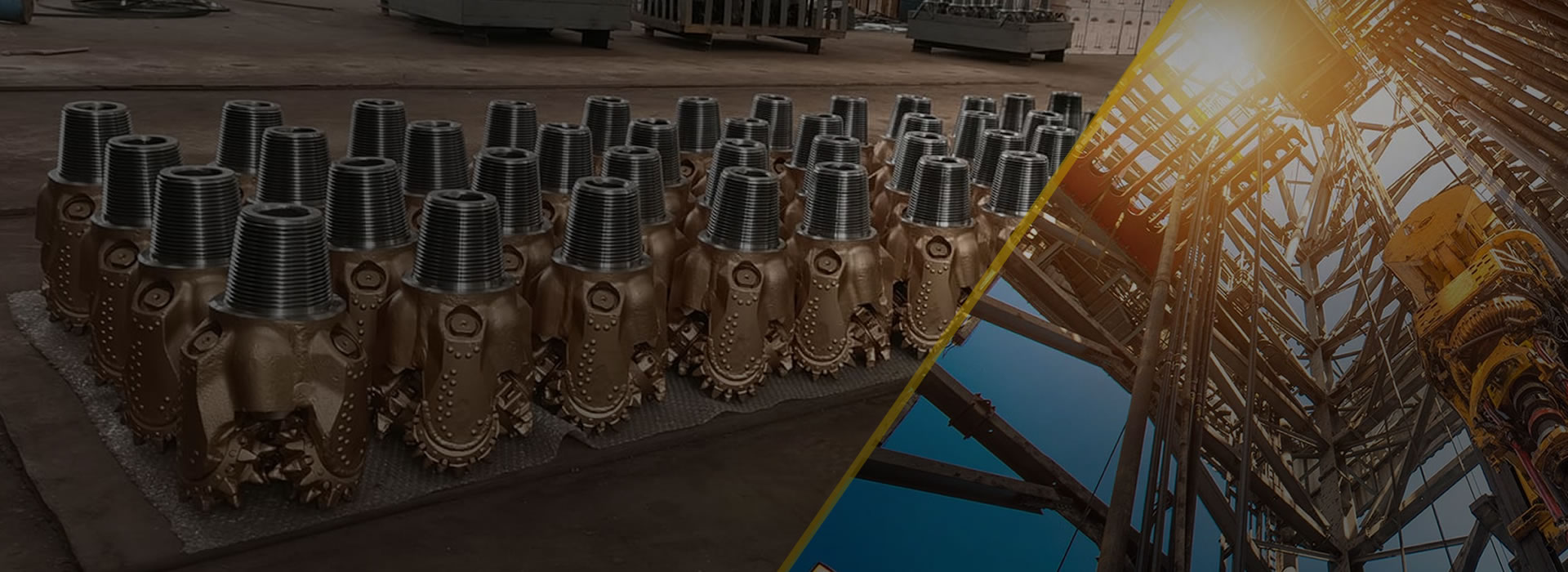

DrillMore Rock Tools Company hat mear as 30 jier de boaringsektor tsjinne. Wy binne spesjalisearre yn it ûntwerp, ûntwikkeling, fabrikaazje en tsjinst fan tricone-bits, DTH-ark, Top Hammer-ark, PDC-bits foar mynbou, boarring, geotermyske boarring, bou, tunneling, steengroeven ...

- Profesjonele leveransier

Foar Drilling IndustrialÚtsûnderlike Customer Service - Design fan hege kwaliteit

Strikte kwaliteitskontrôleKonsintrearje op kompetitive

Lêste Nijs & Updates