Kubowola Kwanu Kwabwino Kwambiri

Sakatulani Zogulitsa Zamagulu

3.4k

TIMU YA PROFESSIONAL

Engineer ndi technician amakonza zida zoyenera za vuto la abrasion.

25+

R&D

Tikupitiliza kukonza makina athu ndikuwonetsetsa kuti zida zamakono zili zokhazikika ndikupangira zida zatsopano kuti zigwirizane ndi vuto latsopano la abrasion.

18+

PA SITE SERVICE ILIPO

Thandizo laukadaulo la 7x24h ndipo timatenga udindo wa 100% pamavuto athu

5.9%

Thandizo lamakasitomala

Gulu laukadaulo & lazamalonda limatsata pempho lililonse la alangizi kapena zitsanzo kapena kutumiza.

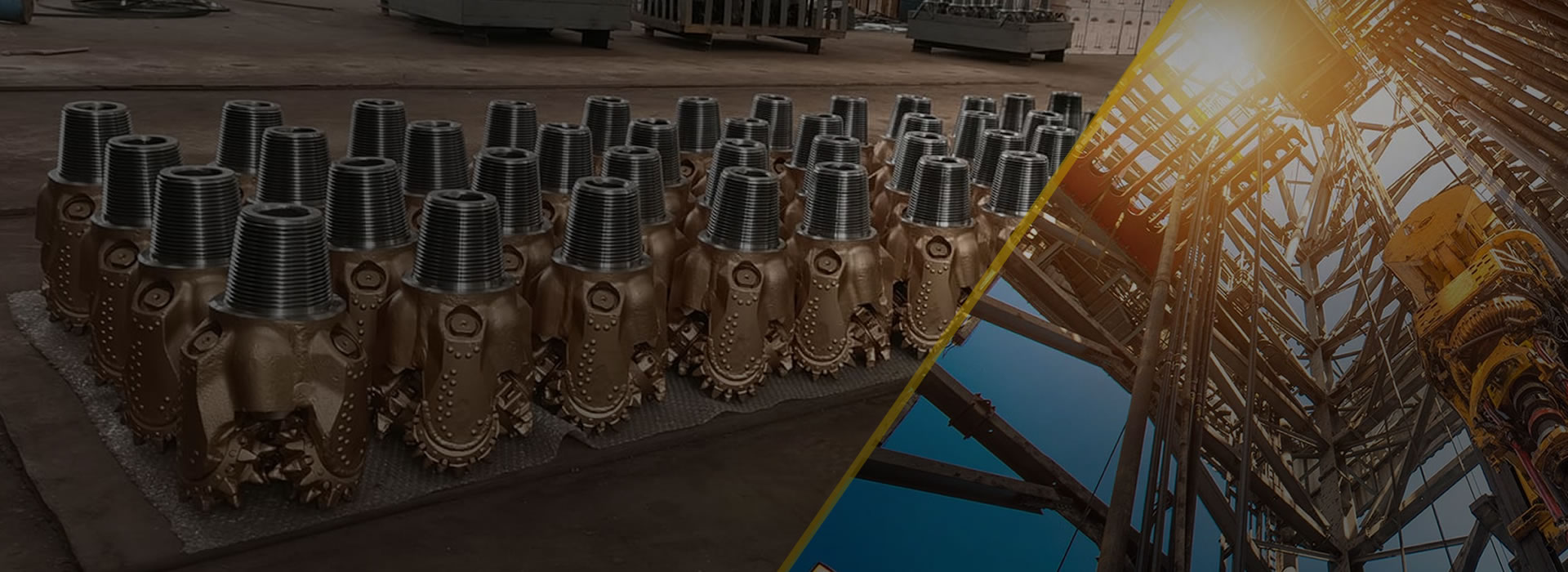

Timapereka Zida Zobowola Zokhazikika

Professional Service

Professional Service

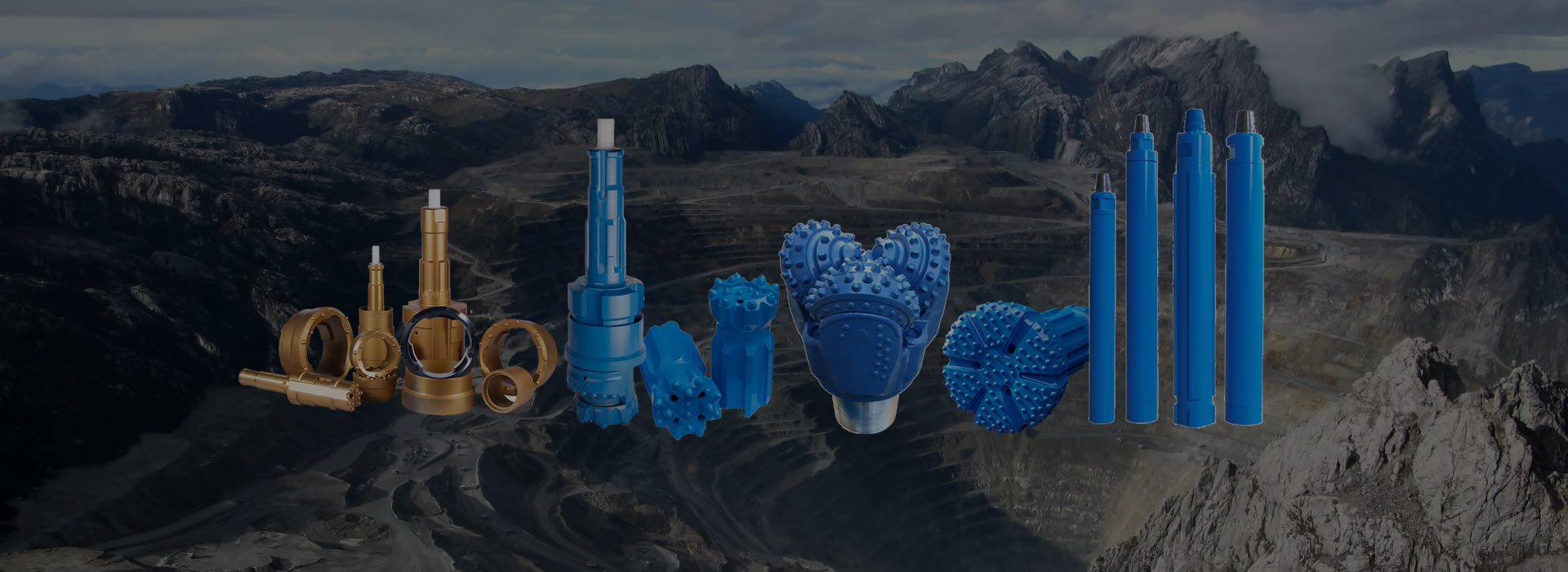

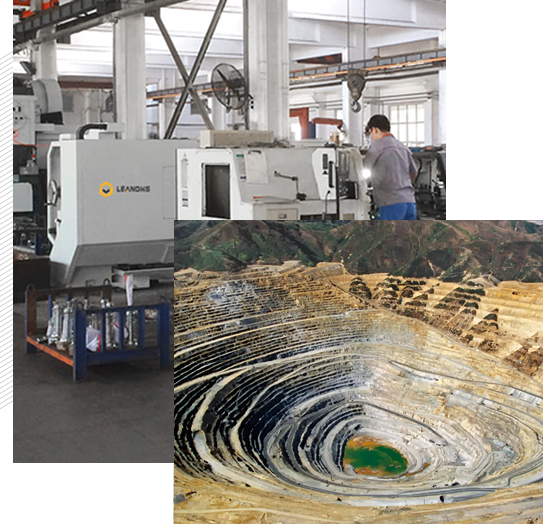

Kampani ya DrillMore Rock Tools yagwira ntchito yobowola kwazaka zopitilira 30. Ndife okhazikika pakupanga, kupanga, kupanga, ndi ntchito za ma tricone bits, zida za DTH, Top Hammer Tools, PDC Bits for Mining, Kubowola, Kubowola kwa Geothermal, Construction, Tunneling, Quarrying...

- Professional Supplier

Kwa Drilling IndustrialUtumiki Wamakasitomala Wapadera - High Quality Design

Kuwongolera Kwabwino KwambiriLimbikitsani Kupikisana

Nkhani Zaposachedwa & Zosintha