您最佳的鑽孔選擇

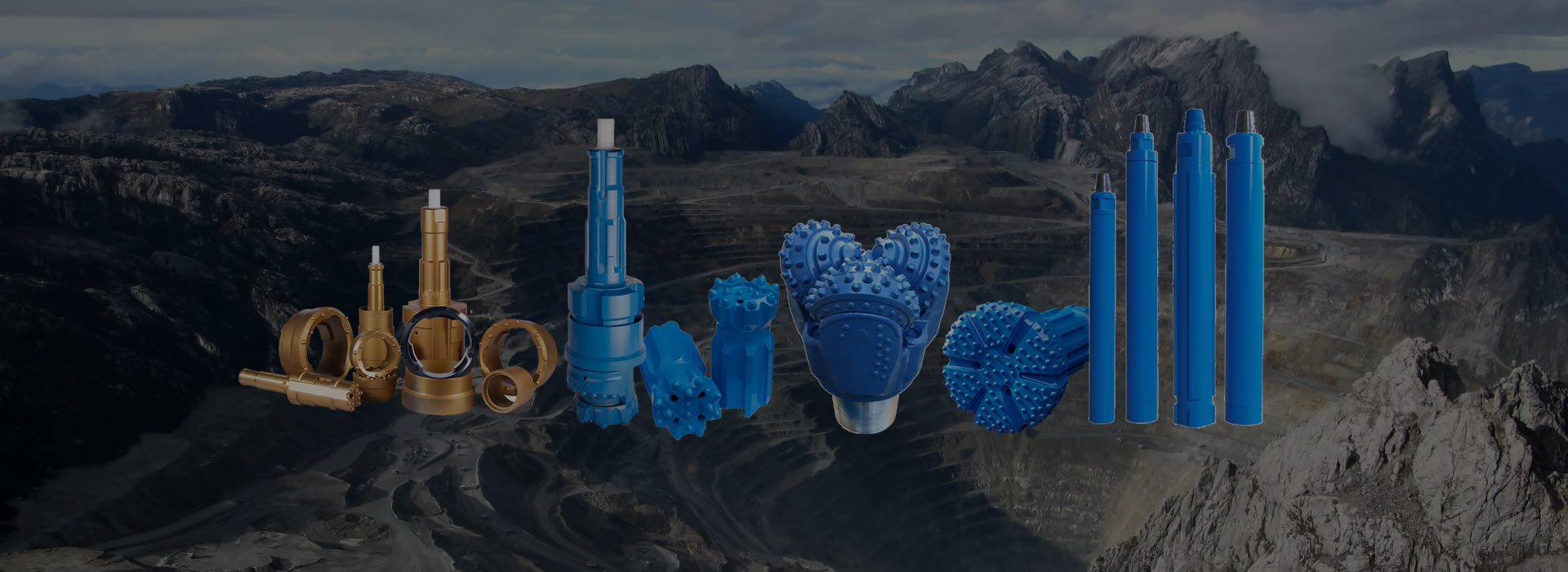

瀏覽產品類別

3.4k

專業團隊

工程師和技術人員針對磨損問題組織正確的材料。

25+

研發

我們不斷改進我們的系統,確保當前材料的質量穩定,並提出新的複合材料以適應新的磨損問題。

18+

提供現場服務

7x24 小時技術支持,我們對我們的問題承擔 100% 的責任

5.9%

客戶服務

技術和商業團隊跟進每一個關於顧問或樣品或裝運的請求。

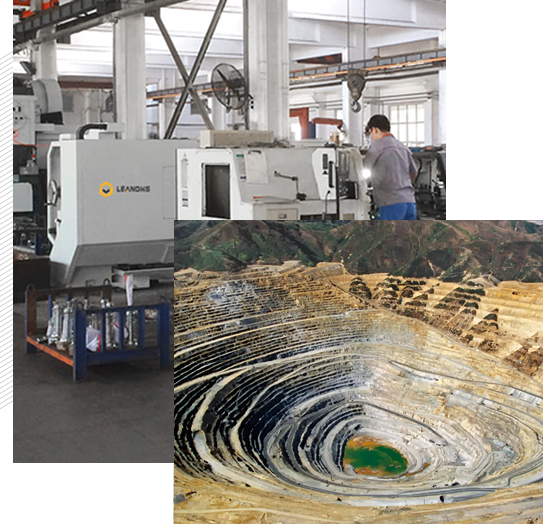

我們提供耐用的鑽孔工具

專業服務

專業服務

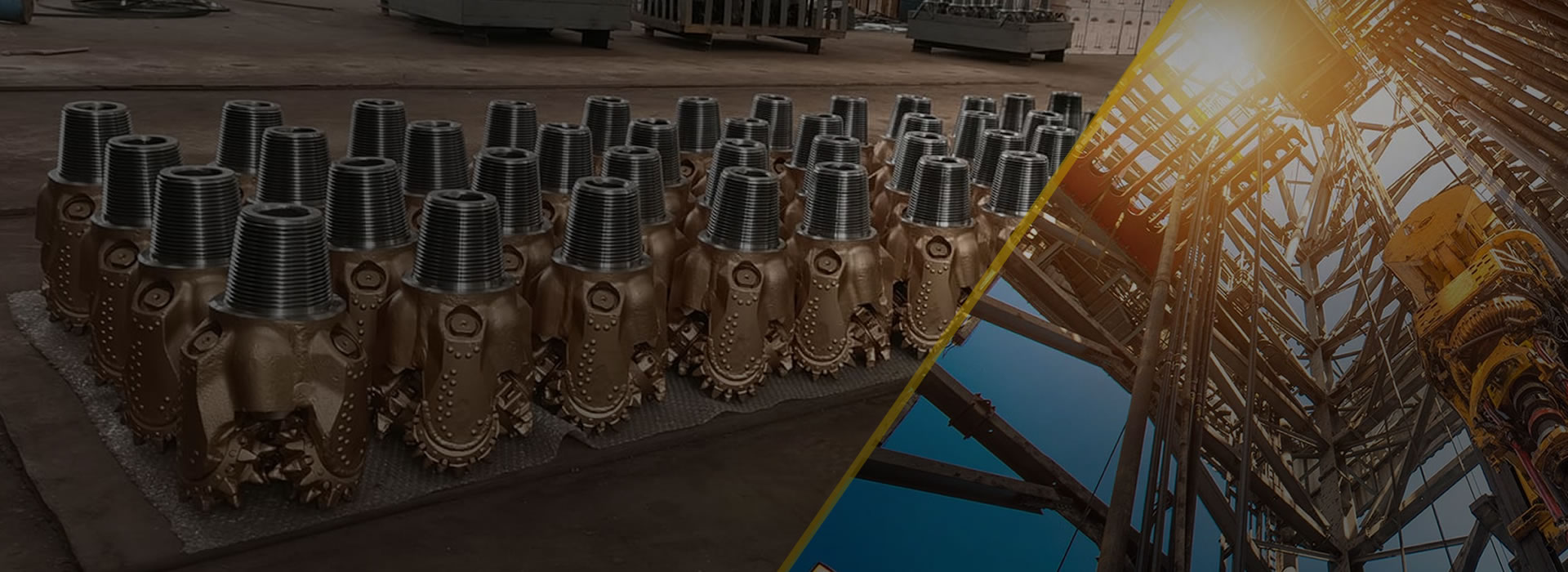

DrillMore Rock Tools Company 為鑽井行業服務了 30 多年。我們專業從事三牙輪鑽頭、潛孔工具、頂錘工具、PDC 鑽頭的設計、開發、製造和服務,適用於採礦、鑽井、地熱鑽探、建築、隧道、採石……

- 專業供應商

用於鑽井工業卓越的客戶服務 - 高品質設計

嚴格的質量控制專注於競爭

最新消息和更新