Lau Filifiliga vili Sili

Su'esu'e Vaega o Oloa

3.4k

'AU FA'ATASI

E fa'atulaga e Inisinia ma tekinisia mea sa'o mo fa'afitauli abrasion.

25+

R&D

O lo'o fa'aauau pea le fa'aleleia atili o la matou faiga fa'amautinoa le mautu lelei o mea o lo'o iai nei ma fa'ailoa mai le tu'ufa'atasiga fou e fetaui ma fa'afitauli fou abrasion.

18+

I LE SITE AUAUNA E MAUA

7x24h lagolago faʻapitoa ma matou te tauaveina 100% tiute i luga o la matou faʻafitauli

5.9%

Auaunaga i tagata

Fa'atekinisi & fa'apisinisi e tulitatao talosaga uma ile faufautua po'o fa'ata'ita'iga po'o uta.

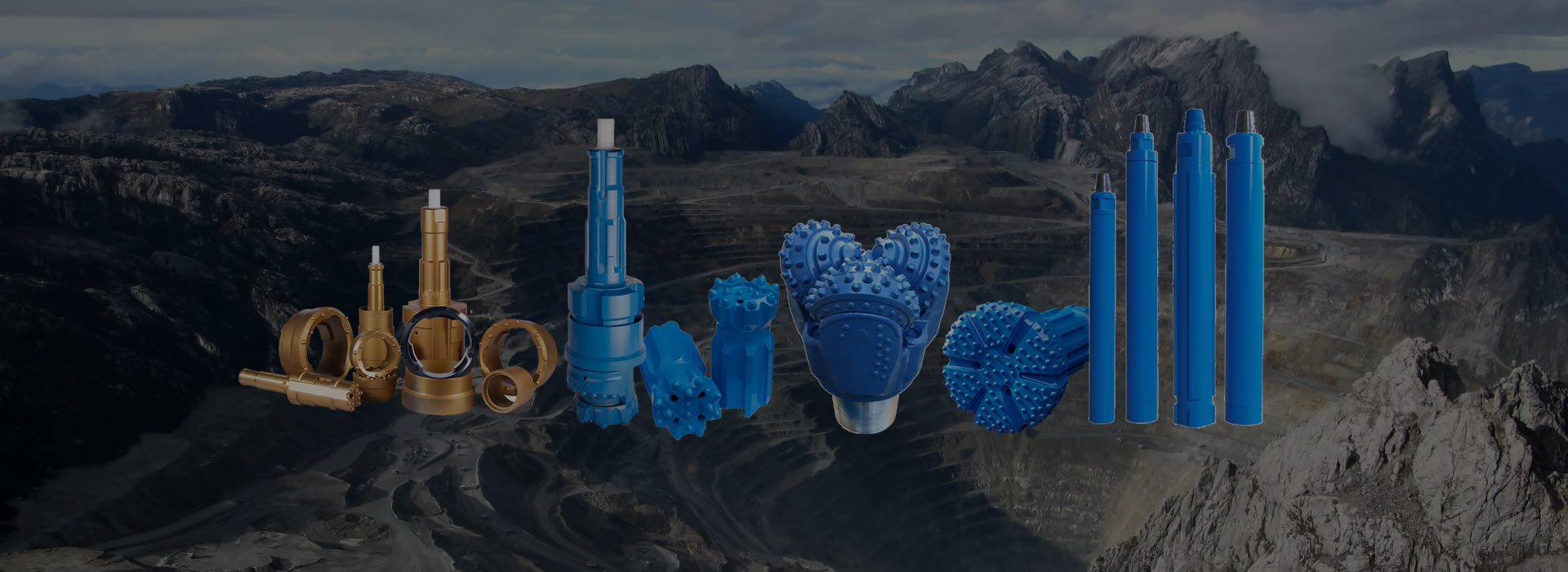

Matou te ofoina atu mea faigaluega viliina tumau

Au'aunaga fa'apolofesa

Au'aunaga fa'apolofesa

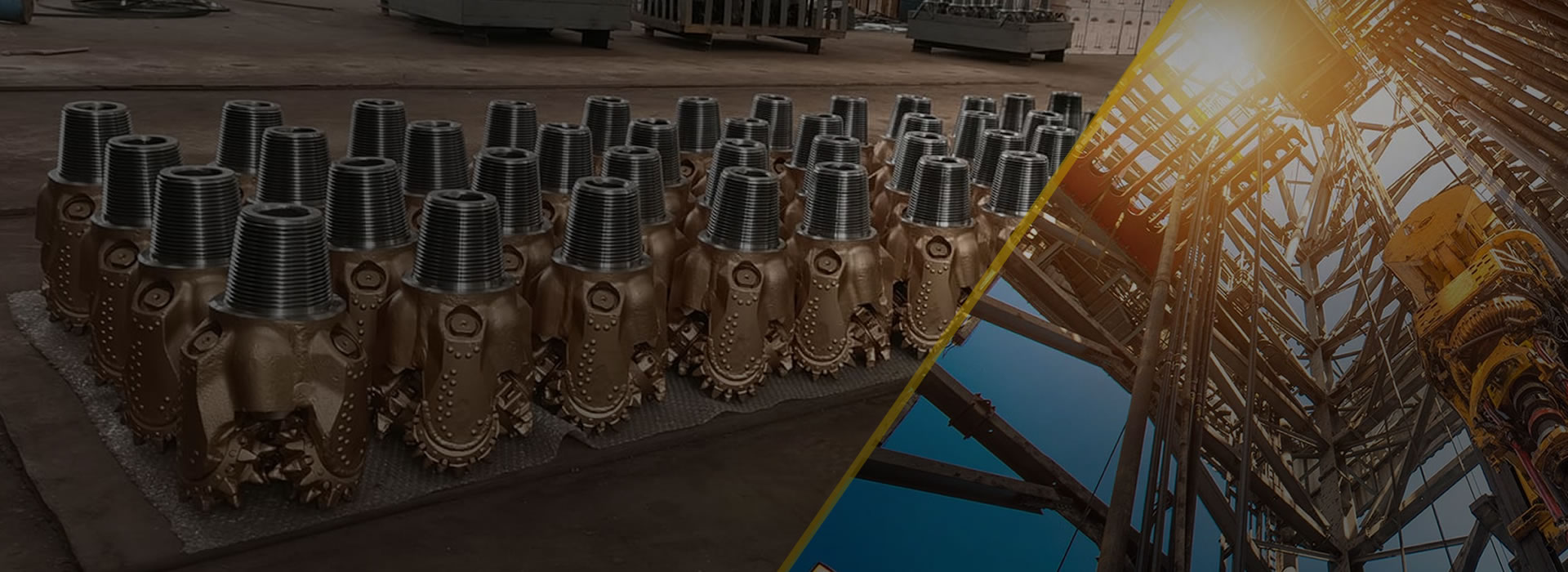

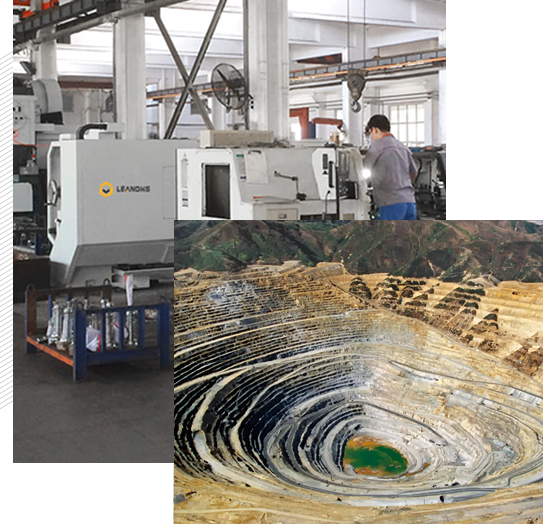

DrillMore Rock Tools Company ua tautuaina le alamanuia vili mo le silia ma le 30 tausaga. Matou te faʻapitoa i le mamanu, atinaʻe, gaosiga, ma le tautua o tricone bits, DTH tools, Top Hammer Tools, PDC Bits for Mining, Well drilling, Geothermal vili, Faufale, Tunneling, Quarrying...

- Fa'apolofesa Fa'atau

Mo Alamanuia viliinaAu'aunaga Tulaga Fa'atau - Fuafuaga Tulaga Maualuga

Pulea leleiTaulai atu i le Tauvaga

Tala Fou & Fa'afouga