Rẹ ti o dara ju liluho Yiyan

Kiri Products Isori

3.4k

EGBE OLOGBON

Onimọ-ẹrọ ati onimọ-ẹrọ ṣeto awọn ohun elo to tọ fun iṣoro abrasion.

25+

R&D

A tẹsiwaju ilọsiwaju eto wa rii daju pe didara iduroṣinṣin ti awọn ohun elo lọwọlọwọ ati daba akojọpọ tuntun lati baamu iṣoro abrasion tuntun.

18+

LORI IṢẸ NIPA SITE

7x24h atilẹyin imọ-ẹrọ ati pe a gba ojuse 100% lori iṣoro wa

5.9%

Iṣẹ onibara

Imọ-ẹrọ & ẹgbẹ iṣowo tẹle gbogbo ibeere lori alamọran tabi awọn ayẹwo tabi awọn gbigbe.

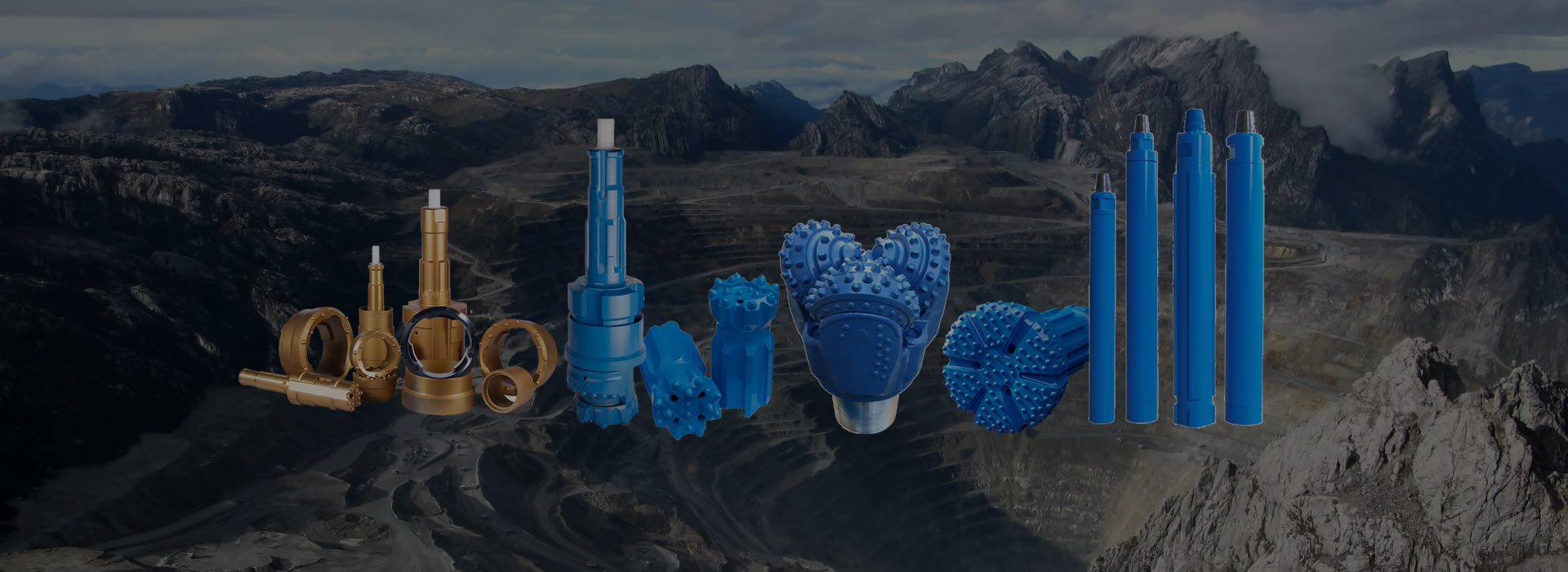

A Nfun Awọn Irinṣẹ Liluho Alailowaya

Ọjọgbọn Service

Ọjọgbọn Service

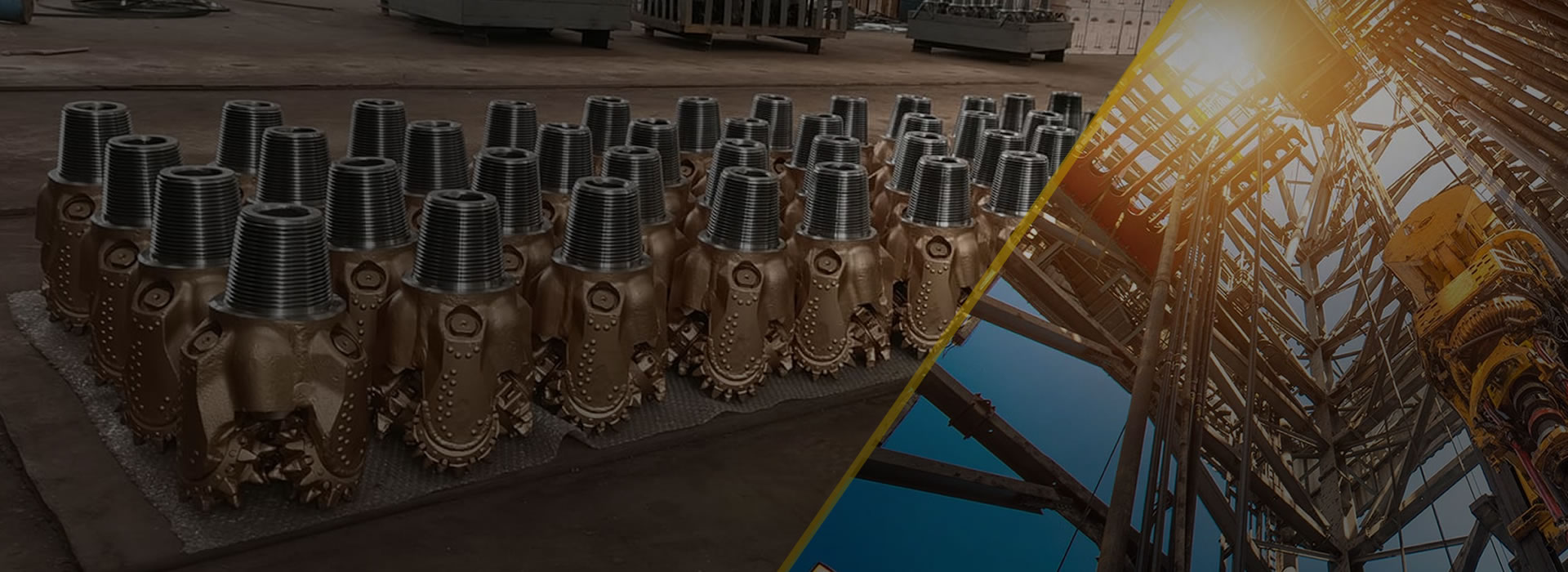

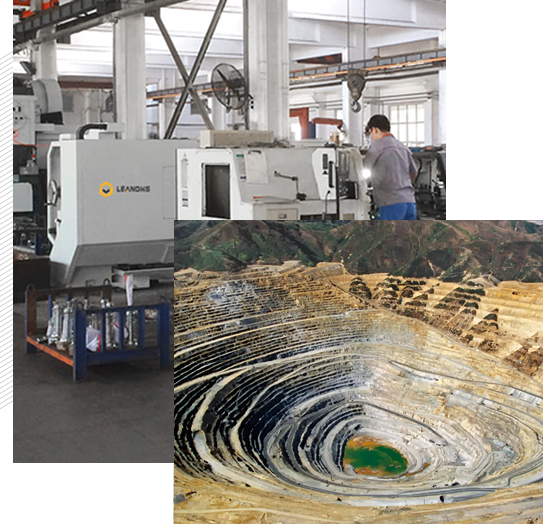

DrillMore Rock Tools Company ti ṣiṣẹ ile-iṣẹ liluho fun ọdun 30 ju. A ṣe amọja ni apẹrẹ, idagbasoke, iṣelọpọ, ati iṣẹ ti awọn bit tricone, awọn irinṣẹ DTH, Awọn irinṣẹ Hammer Top, Awọn Bits PDC fun Iwakusa, Liluho daradara, Liluho Geothermal, Ikọle, Tunneling, Quarrying...

- Olupese Ọjọgbọn

Fun Liluho IndustrialIyatọ Onibara Service - Apẹrẹ Didara to gaju

Iṣakoso Didara to munaKoju lori Idije

Titun News & Updates