Pi bon chwa foraj ou a

Browse Kategori pwodwi yo

3.4k

EKIP PWOFESYONÈL

Enjenyè ak teknisyen òganize materyèl kòrèk pou pwoblèm fwotman.

25+

R&D

Nou kontinye amelyore sistèm nou an asire bon jan kalite ki estab nan materyèl aktyèl yo ak sijere nouvo konpoze anfòm nouvo pwoblèm fwotman.

18+

SÈVIS SOU SITE DISPONIB

7x24h sipò teknik epi nou pran 100% responsablite sou pwoblèm nou an

5.9%

Sèvis Kliyantèl

Ekip teknik ak komèsyal swiv chak demann sou konsiltan oswa echantiyon oswa anbakman.

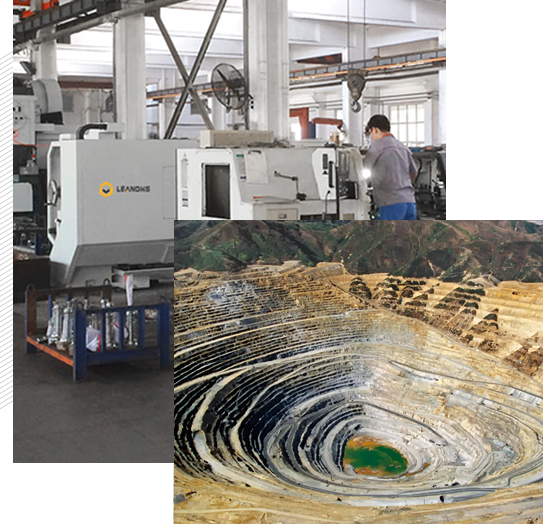

Nou ofri zouti perçage dirab

Sèvis Pwofesyonèl

Sèvis Pwofesyonèl

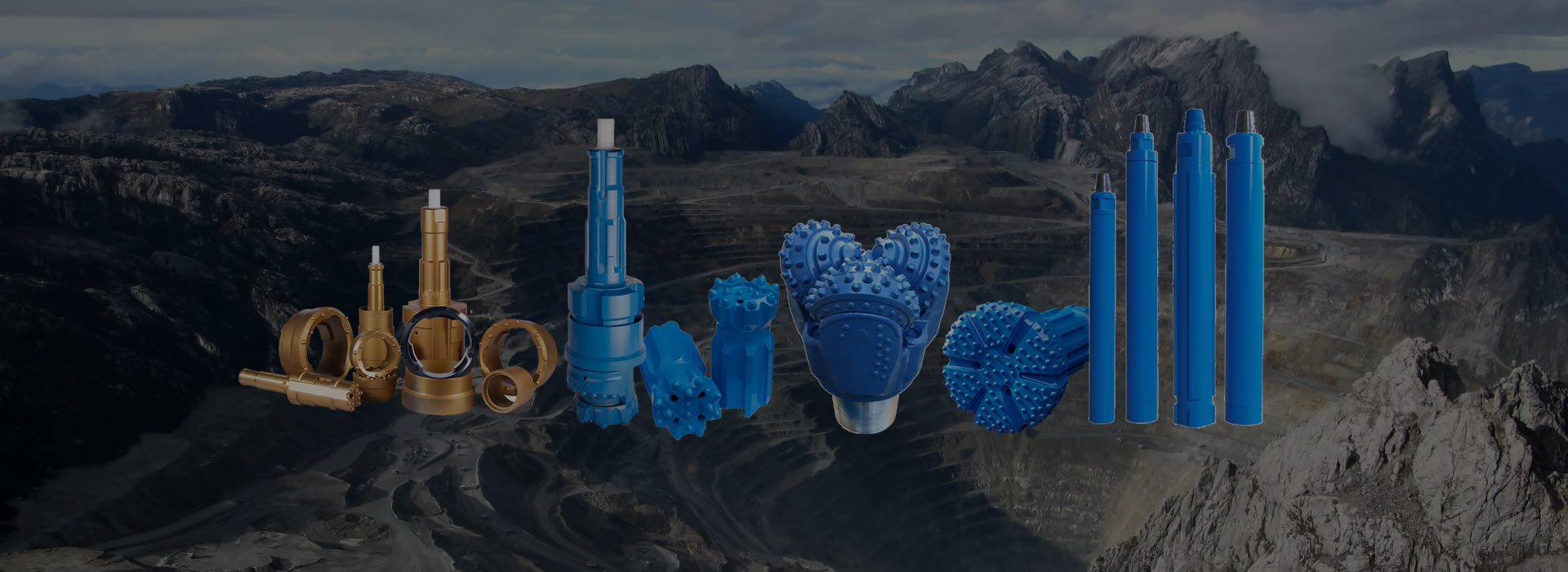

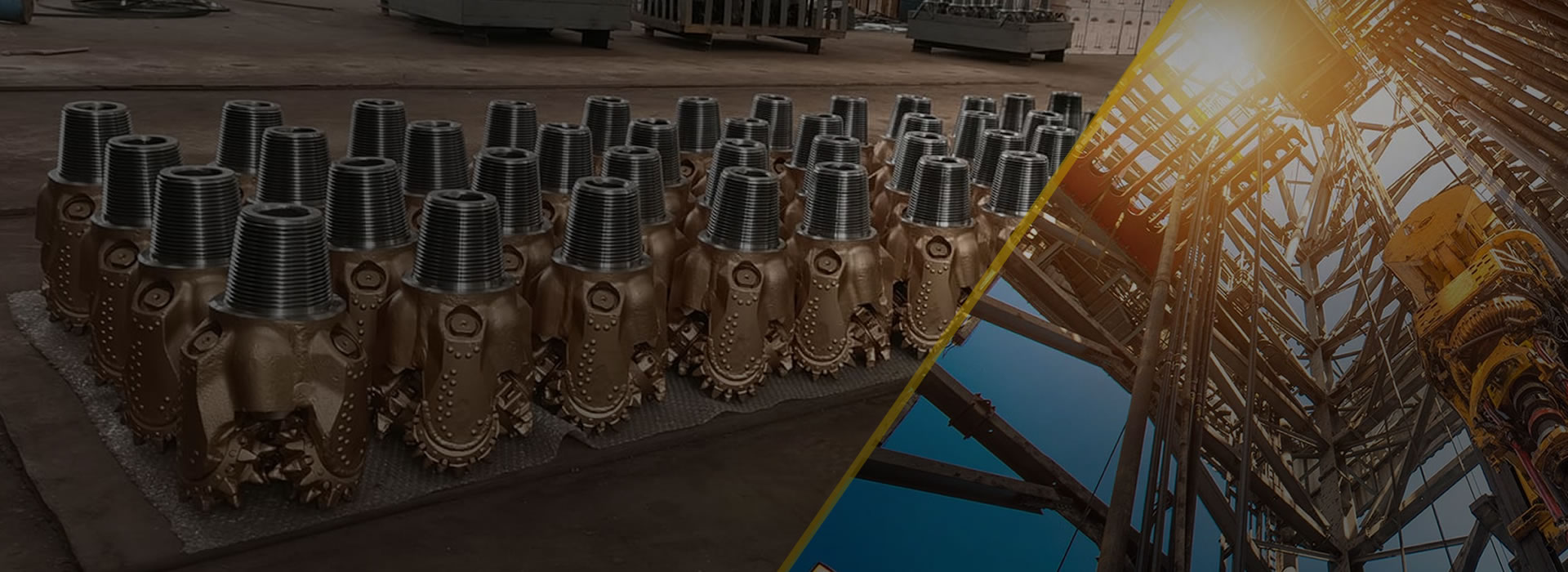

DrillMore Rock Tools Company te sèvi endistri perçage pou plis pase 30 ane. Nou espesyalize nan konsepsyon, devlopman, fabrike, ak sèvis tricone bits, zouti DTH, Top Hammer Tools, PDC Bits pou min, perçage byen, perçage jeotèmik, konstriksyon, Tunneling, karyè...

- Founisè pwofesyonèl

Pou Forage EndistriyèlSèvis Kliyan eksepsyonèl - Segondè Kalite Design

Kontwòl Kalite strikKonsantre sou konpetitif

Dènye Nouvèl ak Mizajou