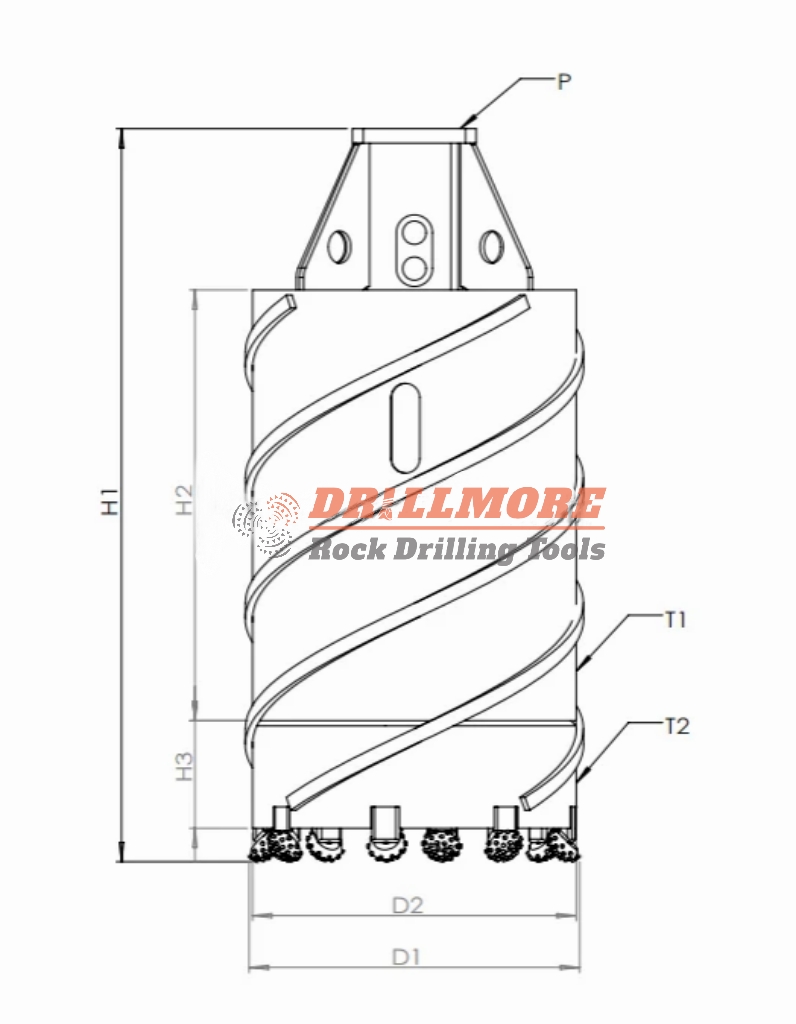

Roller bit core barrel

Roller bit is a kind of cut pick use in deep foundation drilling work, it usually installed in core barrel, suite for very hard rock layer drilling.

When you start a foundation work such as bored pile, pillar, drill shaft,cassion pile work, the layer is very hard drilling use bullet teeth, roller bit will be a best option.

Unlike tricone bits that drill by a crushing action, the single cone bits drill by a scraping action. Thus, the single cone drill bits utilize wear resistant tungsten carbide inserts in the cutting structure.

The Tricone bit palm cutters installed on Hole Openers, Core Barrels to drilling water well, oil field, construction, geothermal, directional boring, and underground foundation, Crossing, horizontal directional drilling.

1.Drilling with the method of rolling and squeezing can increases the anti-wear ability of the barrel;

2.Small barrel facilitates the coring operation,large barrel performs stage breaking

Specifictions:

| Diameter (mm) | Bucket height(H1) | Height(H2) | Height(H3) | Bucket Thickness (T1) | Base plate thickness (T2) | Maximum diameter (D1) | Barrel diameter (D2) | |||||

| 500 | 1750 | 1050 | 150 | 30 | 30 | 480 | 426 | ||||||

| 600 | 1750 | 1050 | 150 | 16 | 40 | 580 | 520 | ||||||

| 800 | 1750 | 1050 | 150 | 16 | 40 | 780 | 720 | ||||||

| 1000 | 1750 | 1050 | 150 | 16 | 40 | 980 | 920 | ||||||

| 1200 | 1750 | 1050 | 150 | 16 | 40 | 1180 | 1120 | ||||||

| 1500 | 1750 | 1050 | 150 | 16 | 40 | 1480 | 1420 | ||||||

| 1800 | 1550 | 850 | 200 | 20 | 40 | 1780 | 1720 | ||||||

| 2000 | 1450 | 700 | 200 | 20 | 40 | 1980 | 1920 | ||||||

| 2200 | 1450 | 700 | 200 | 25 | 40 | 2180 | 2120 | ||||||

| 2500 | 1250 | 500 | 200 | 25 | 40 | 2480 | 2420 | ||||||

| 2600 | 1250 | 500 | 200 | 30 | 50 | 2580 | 2520 | ||||||

| 3000 | 1250 | 500 | 200 | 30 | 50 | 2980 | 2920 | ||||||

Why choose DrillMore and what are our advantages?

DrillMore's Roller Cone Bit is O type rubber sealed rolling bearing Roller Cone Bit, For high penetration rate drilling, it is an ideal and economical tool. It's main structural features:

1.Sealed rolling sliding bearing structure: on the main runway, the cylindrical roller is placed in the groove of the cone and the small runway use sliding wear resistant bushing, this enlarged the journal size. so it has the ability to withstand higher drilling pressure and adapt to high speed.

2.The surface of the thrust bearing pair is subjected to wear reduction treatment and hardening treatment, It improved the bearing capacity and bearing anti-bite ability.

3.A new type of grease that can withstand 250 degree of high temperature and wear resistance is adopted. It improved the high temperature resistance of the sealing lubrication system. At the same time, the optimized sealing structure is adopted to avoid the wear of the O-ring by the roller, and the life of the sealing ring is improved, thereby improving the service life of the roller bit.

4. Insert tricone bits adopts high strength and high toughness carbide teeth,which improves the impact resistance of the teeth and reduces the rate of tooth breakage.

5. Optimized design of the number of rows, teeth number, teeth expose height and unique alloy tooth profile, made the cutting ability and cutting speed of the tricone bits fully realized.

Related images:

DrillMore Rock Amathuluzi

I-DrillMore inikezelwe empumelelweni yamakhasimende ethu ngokuletha izingcezu zokumba kuhlelo ngalunye. Sinikeza amakhasimende ethu embonini yokumba izinto eziningi ongakhetha kuzo, uma ungakutholi okuncane okufunayo sicela uxhumane nethimba lethu labadayisi ngokulandelayo ukuze uthole ibhithi elilungile lohlelo lwakho lokusebenza.

Igatsha eliphethe:XINHUAXI ROAD 999, LUSONG DISTRICT, ZHUZHOU HUNAN CHINA

Ucingo: +86 199 7332 5015

I-imeyili: [email protected]

Sishayele manje!

Silapha ukuzosiza.

Ikheli lakho le-imeyili ngeke lishicilelwe. Izinkambu ezidingekayo zimakwe nge *