Different Types Of Mining And Well Drilling Bits

Different Types Of Mining And Well Drilling Bits

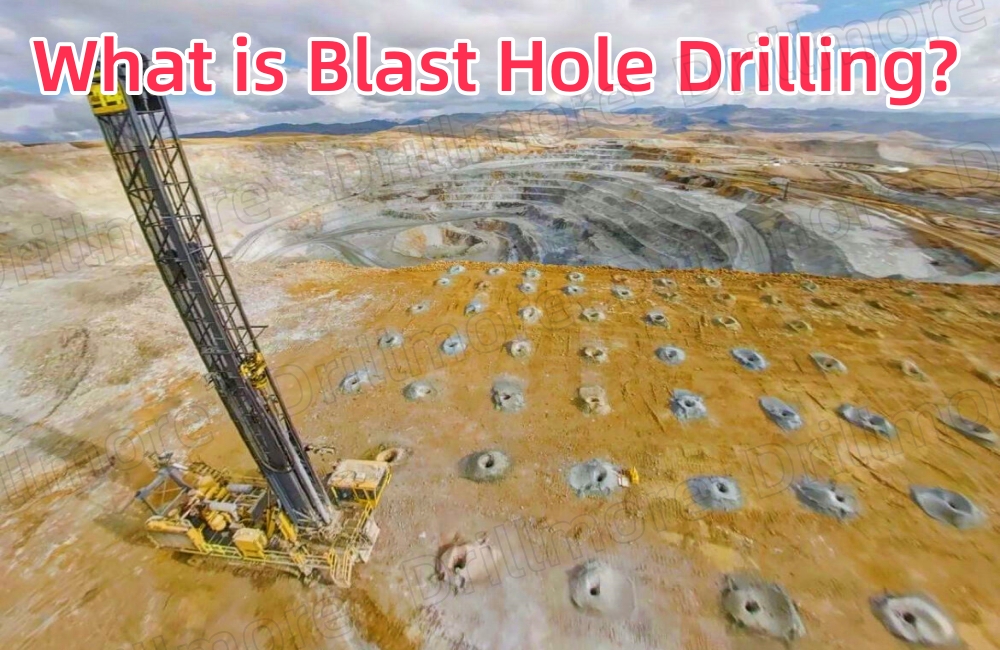

Mining and well drilling bits are hole boring bits that drill through and penetrate soft and hard rock materials. They are used in mining, well drilling, quarrying, tunneling, construction, geological exploration, and blasting applications.

Mining and well drilling bits typically feature a threaded connection for attachment to a drillstring and a hollow body through which drill fluids are circulated. Drill fluids are required to clear drill cuttings, cool the bit, and stabilize the borehole wall. Types of well drilling bits include the following:

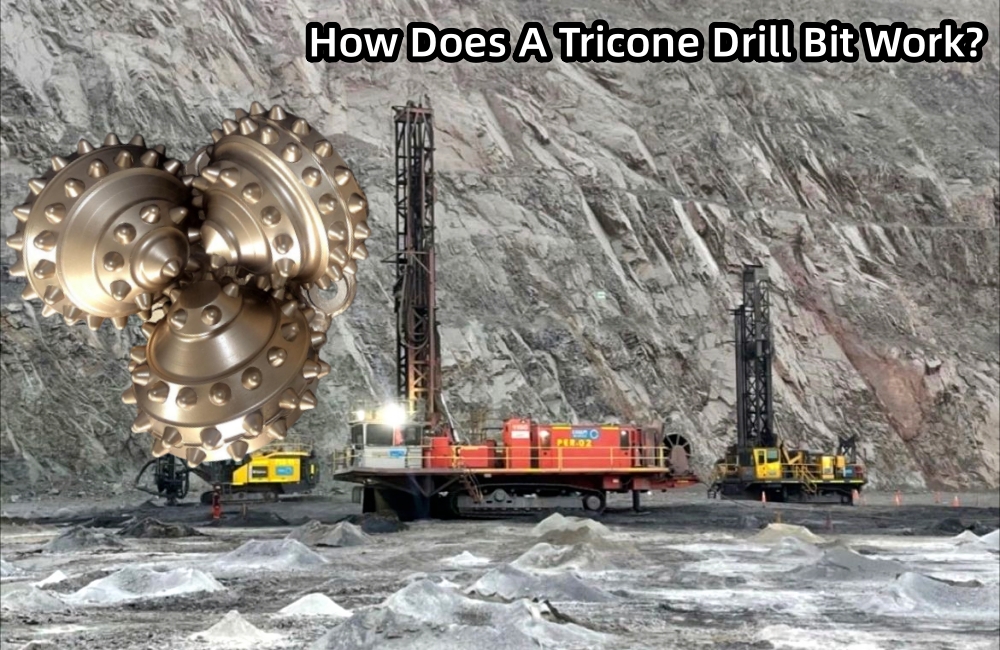

Tri-cone or roller bits contain three toothed cones, each with a journal angle pitched towards the bit’s primary axis. The journal angle is modified according to the hardness of the formation. The teeth of each cone mesh against one another to bore through solid earth. The bit is driven by the weight-on-bit (WOB) while being pulled by the rotary action of the drill bit head.

Down-the-hole (DTH) hammer bits are used with Down-the-hole hammers for drilling holes through a wide range of rocks types. In conjunction with DTH hammers, drill hammer bits are designed with a splined drive for rotating the bit in the ground. DTH bits are fixed-head bits that have conical or chisel bit inserts aligned in a matrix about the drill bit head. The head configuration of the bit may be convex, concave, or flat.

PDC bits with polycrystalline diamond compact (PDC) inserts may be referred to as PDC bits. Unlike tricone bits, PDC drill bits are one piece bodies with no moving parts and engineered to last; every bit is designed in-house for performance, consistency and dependability. Choose Matrix or high-strength steel to suit different drilling applications.

Button bits are same with DTH bits fixed-head bits that have conical or chisel bit inserts aligned in a matrix about the drill bit head. The head configuration of the bit may be convex, concave, or flat. Button bit is the all round bit suitable for most hard rock, top hammer drilling applications.

Cross bits and chisel bits are fixed-head bits that have hardened steel or carbide blades. Chisel bits are defined by a single blade while cross bits contain two or more blades that cross at the center of the bit. The blades are typically tapered down toward the cutting surface.

Your email address will not be published. Required fields are marked with *