Matrix PDC Bit For Oil, Geothermal, Water well Drilling

The hardness of PDC matrix bit is high and corrosive, so the PDC matrix bit has a long single life and high inlet, which is widely used in natural gas drilling and deep wells.

The PDC matrix bit is sintered with tungsten carbide powder, brazed on the tungsten carbide body with synthetic PDC cutters, and diameter retaining with artificial heat-stabilized polycrystalline diamond. The tungsten carbide body has high erosion resistance, wear resistance, high strength and good diameter retaining effect. The bit waterhole area can be designed according to the hydraulic parameters required by the drilling process, providing greater flexibility. The shape of the body can be designed according to the characteristics of the formation, and the change of the shape of the body is only required to change the mold without adding equipment.

What Matrix PDC Bit can DrillMore provide?

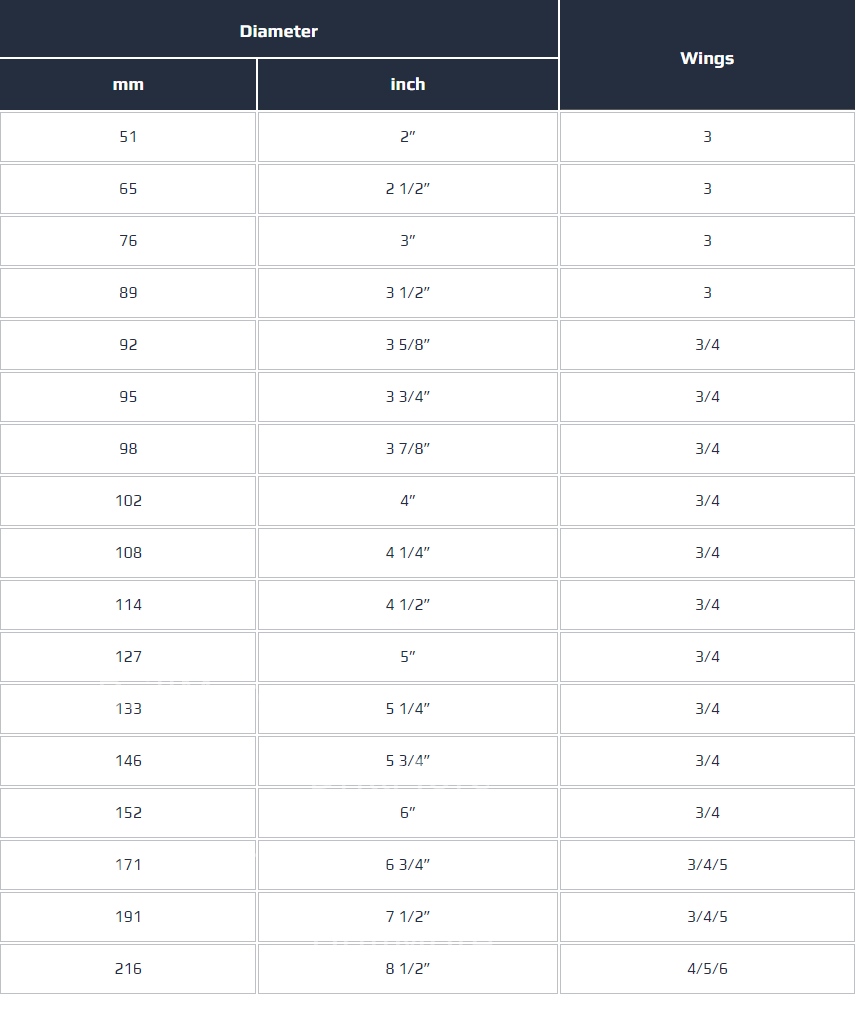

DrillMore mainly provide PDC bits from size 51mm(2") to 216mm(8 1/2"), with 3/4/5/6 wings which is widely used in natural gas drilling and deep wells.

Features Of DrillMore Matrix PDC Bit:

1. The upper part of the Matrix PDC Bit is made of steel and the lower part is made of tungsten carbide wear-resistant alloy. The PDC cutting teeth are welded to the pre-set grooves of the body with low temperature welding material. The tungsten carbide body has high hardness and is resistant to erosion, so the Matrix PDC bit has long life and high feed rate, and is widely used.

2. The Matrix PDC bit is mainly used for difficult to drill formations with high gravel and compressive strength. Its own strength is higher than that of steel body bits.

3. Matrix PDC bits have high hardness and wear resistance of cutting teeth due to the use of polycrystalline diamond composite as cutting element.

Method of use a Matrix PDC Bit :

1.PDC bits work best in soft to medium-hard formations with large homogeneous sections. It is not suitable for drilling gravel layers and soft-hard interlaced formations.

2.Use low drilling pressure, high speed and large displacement drilling, the bit is used effectively.

3.Before the drill bit is lowered into the well, the bottom of the well should be cleaned to ensure that there is no metal fallout.

4.When the drill bit first comes down the well, run and use small drilling pressure and low rotational speed, and resume normal drilling after the bottom of the well is formed.

5.PDC bits are integral bits without any moving parts, which are suitable for high speed turbo drilling.

DrillMore Rock Tools

DrillMore is dedicated to the success of our customers by suppling drilling bits to each application. We offers our customers in the drilling industry many options, if you do not find the bit you are looking for please contact our sales team at following to find the correct bit for your application.

Head Office: XINHUAXI ROAD 999, LUSONG DISTRICT, ZHUZHOU HUNAN CHINA

Telephone: +86 199 7332 5015

WhatsApp: https://wa.me/8619973325015

Email: [email protected]

Call us now!

We are here to help.

Your email address will not be published. Required fields are marked with *