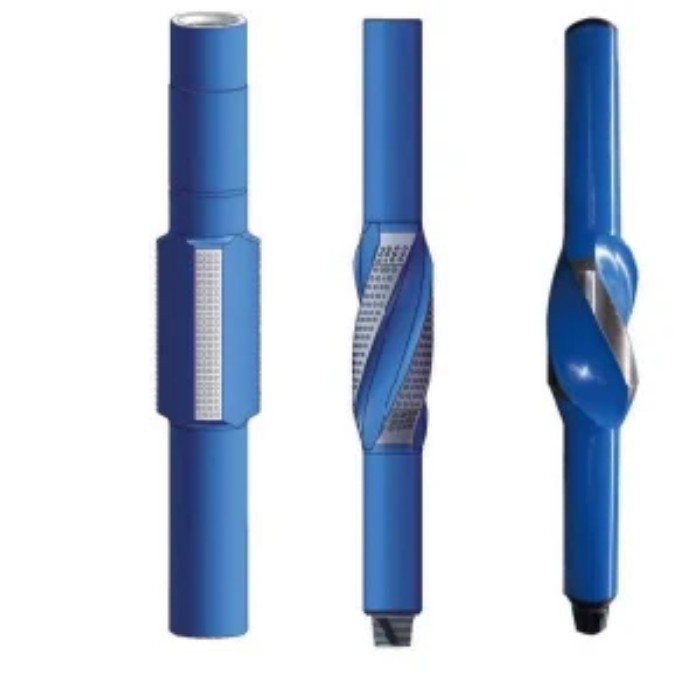

Tricone Bit IADC537 For Borewell Drilling

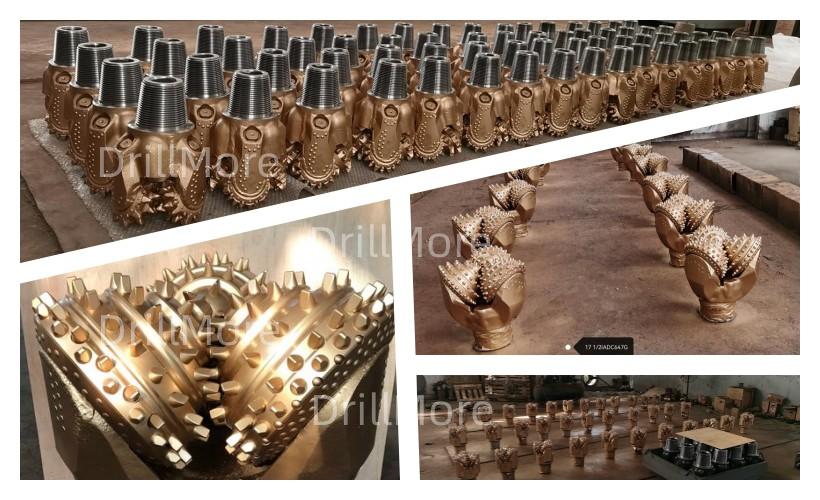

DrillMore provide Mill Tooth Tricone Bits and Tungsten Carbide Insert (TCI) Tricone Bits for Well Drilling, Borehole Drilling, Oil/Gas Drilling, Construction..., IADC537 is the most popular type, which we have big quantities in stock .

Tricone bits IADC537 apply for soft to medium formations with low compressive strength, like medium, soft shake, medium soft limestone, medium soft sandstone, medium formation with harder and abrasive interbeds.

DrillMore's Quality Control

In manufacturing, each process goes through an extensive and painstaking testing, quality control is a process that ensures customers receive products free from defects and meet their needs.

1, Raw material selection: To make a good drill bit, it is necessary to select the best material and gatekeeping the quality of the material. We purchase the high-quality steel and strictly control the material composition and size, it main includes the detection of the shape, diameter, reamed diameter, length composition, and flaw of the raw material, Tungsten Carbide and Grease are also the best raw materials on the market.Besides, we marked every different piece of materials before transferred to the warehouse.

2, In strict accordance with the ISO9001 international standards for production.

Carefully control every step of the production, complete each of the production process,

the production process is including blanking, forging, rough turning, heat treatment,fine turning, quenching, assembling, welding, painting, then storage.

Each working process was full inspected, after the qualification, then move to next working process, which to ensure the 100% qualified rate.

3, Sampling observation, numbered, packing and arrange the shipment.

More type can provide if you have demand.

Contact with Kathy Zhou: [email protected]

DrillMore Rock Tools

DrillMore is dedicated to the success of our customers by suppling drilling bits to each application. We offers our customers in the drilling industry many options, if you do not find the bit you are looking for please contact our sales team at following to find the correct bit for your application.

Head Office: XINHUAXI ROAD 999, LUSONG DISTRICT, ZHUZHOU HUNAN CHINA

Telephone: +86 199 7332 5015

WhatsApp: https://wa.me/8619973325015

Email: [email protected]

Call us now!

We are here to help.

Your email address will not be published. Required fields are marked with *