Performance and Limitations of Tricone Bits in Well Drilling and Mining

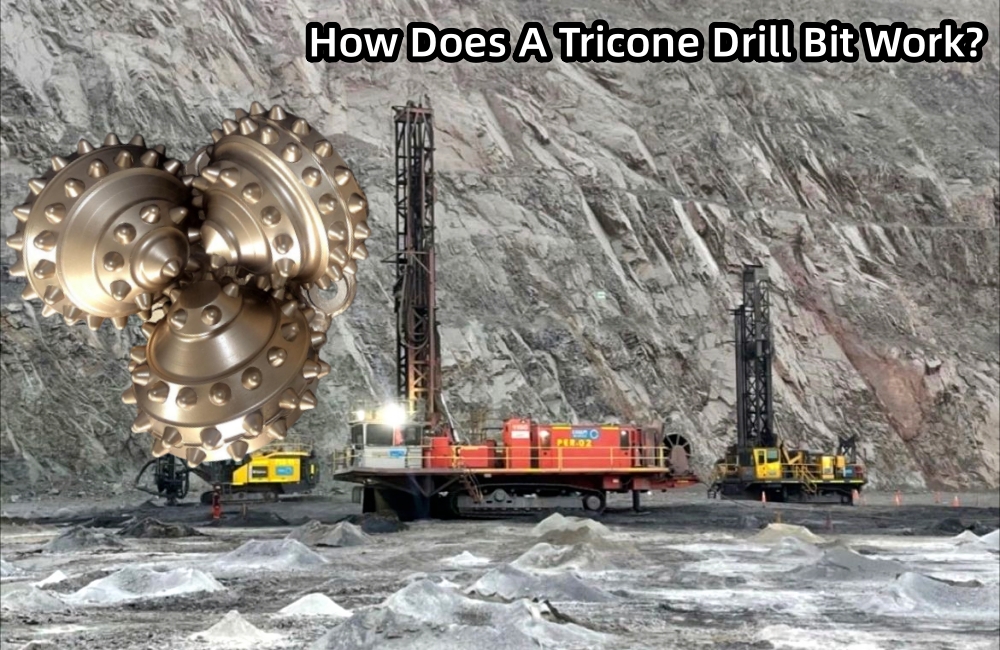

Tricone Bits play a crucial role in the fields of well drilling and mining as essential drilling tools. Their unique design and cutting structure enable them to excel in drilling operations, yet they also face challenges and limitations. This article will delve into the performance and limitations of Tricone Bits in well drilling and mining, providing a better understanding of their advantages and constraints in practical applications.

●Advantages of Tricone Bits

Firstly, let's examine the advantages of Tricone Bits in well drilling and mining.

1. High Efficiency:

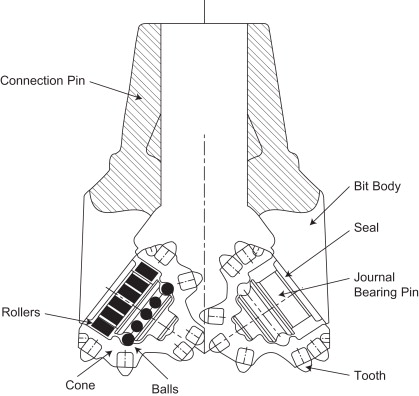

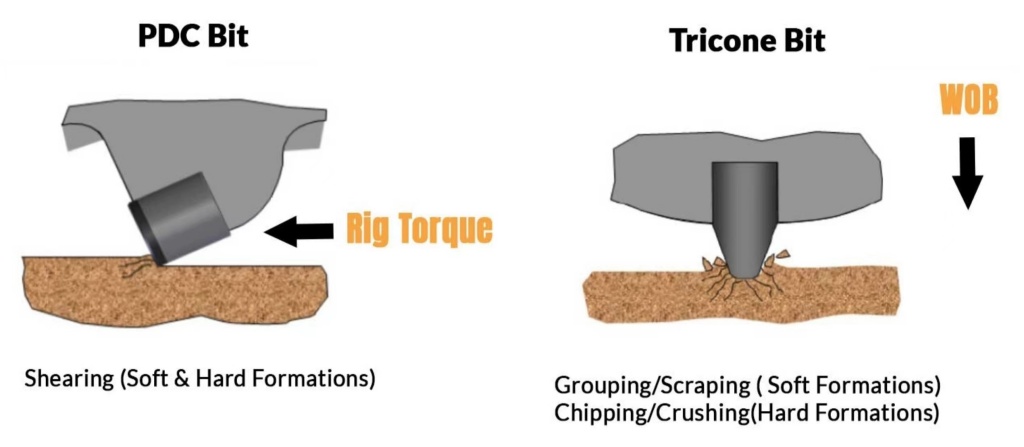

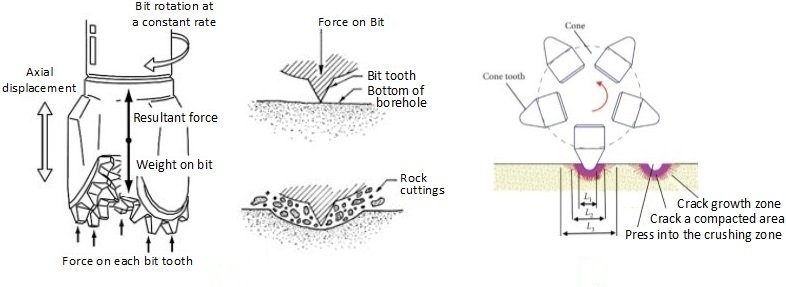

DrillMore's Tricone Bits employ a three-cone design, with each cone equipped with a set of hard alloy drill bits, enabling rotation and cutting during drilling. This design enhances drilling efficiency, allowing rapid penetration through various formations and increasing operational efficiency.

2. Versatility:

Tricone Bits are suitable for different types and hardness of rocks and formations, applicable in both well drilling and mining exploration. They can tackle various geological conditions, including hard rocks, gravel layers, and water-bearing formations. DrillMore's design and manufacturing expertise enables stable operation in complex formations, maintaining high efficiency.

3. Wear Resistance:

Constructed from wear-resistant alloy materials, Tricone Bits have a longer service life. Even in harsh drilling environments, Tricone Bits maintain stable performance and durability over extended periods. DrillMore drill bits utilize high-quality materials and advanced manufacturing processes, undergo rigorous quality control to ensure wear resistance and longevity.

|  |

●Limitations of Tricone Bits

Despite their advantages, Tricone Bits in well drilling and mining also have limitations.

1. High Cost:

Tricone Bits are relatively costly compared to other drill bits, requiring more investment. Especially for small-scale drilling projects, cost may be a significant consideration.

2. Specialized Operation Requirements:

Tricone Bits require professional operation and maintenance to maintain drilling efficiency and bit life. Incorrect operation and maintenance may lead to bit damage or premature failure.

3. Limited Effectiveness in Certain Geological Conditions:

When facing extreme geological conditions such as extremely hard rocks or water-bearing formations, the effectiveness of Tricone Bits may be limited. In such conditions, alternative types of drill bits or drilling methods may need to be considered.

●Conclusion

In summary, Tricone Bits are essential drilling tools in well drilling and mining, offering high efficiency, versatility, and wear resistance. DrillMore's Tricone Bits hold significant advantages in these aspects. However, it's essential to consider their higher cost, specialized operation requirements, and limitations in extreme conditions. Therefore, when selecting and using Tricone Bits, various factors need to be comprehensively considered to ensure smooth drilling operations.We hope this article provides valuable insights into the performance and limitations of Tricone Bits in well drilling and mining.

If you have any questions or need more information about DrillMore's Tricone Bits or other drilling tools, please feel free to contact us. We are committed to providing professional consultation and services.

Your email address will not be published. Required fields are marked with *