What is Rotary Bits for Rock Drilling?

What is Rotary Bits for Rock Drilling?

Rotary drill bits for rock drilling are specialized tools used in various industries such as mining, oil and gas exploration, construction,

and geothermal drilling to penetrate and excavate rock formations. They are essential components of rotary drilling systems and

come in different types, each designed for specific rock types and drilling conditions. Here's an overview of the three main types

of rotary drill bits used for rock drilling:

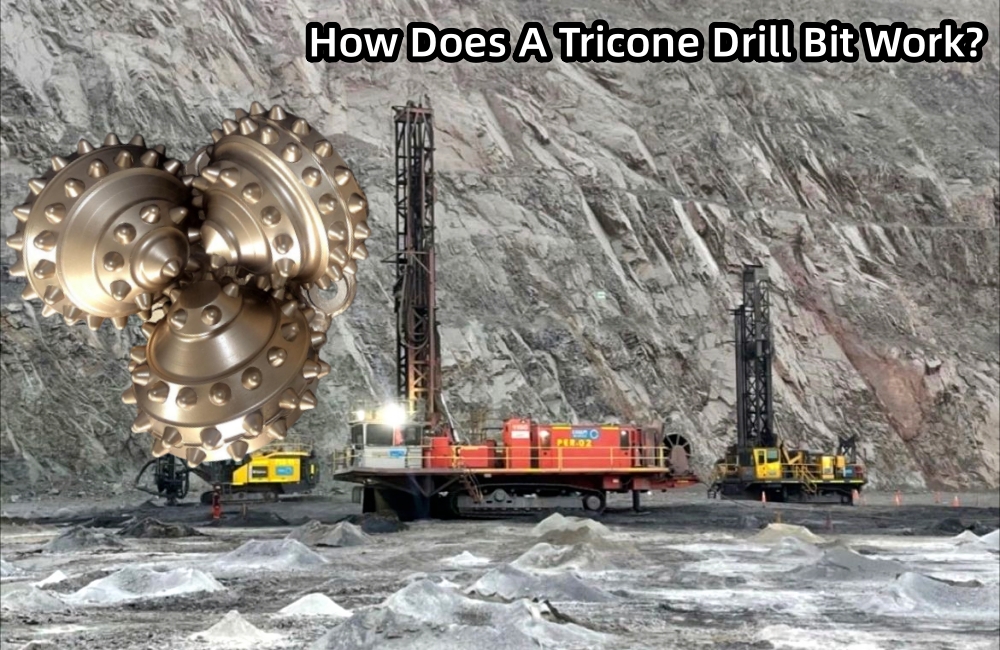

1. Tricone Bit (Three-Cone Drill Bit):

- Design: Tricone bits consist of three rotating cones with tungsten carbide or diamond inserts that crush and disintegrate rock

formations as they rotate.

- Usage: They are versatile and can be used in a wide range of rock formations, including soft, medium, and hard formations.

- Advantages: Tricone bits offer good performance in various drilling conditions, provide excellent stability, and are known for

their durability and versatility.

- Applications: Tricone bits are commonly used in oil and gas drilling, mining, water well drilling, and geothermal drilling.

2. PDC Bit (Polycrystalline Diamond Compact Bit):

- Design: PDC bits feature fixed cutters made of polycrystalline diamond materials bonded to the bit body, providing continuous

cutting edges.

- Usage: They excel in drilling through hard and abrasive rock formations, such as shale, limestone, sandstone, and hardpan.

- Advantages: PDC bits offer high penetration rates, increased durability, and longer bit life compared to traditional tricone bits

in certain rock types.

- Applications: PDC bits are widely used in oil and gas drilling, geothermal drilling, directional drilling, and other applications

requiring efficient rock penetration.

3. Drag Bit:

- Design: Drag bits, also known as fixed-cutter bits, have blades or cutters attached to the bit body and do not have rotating cones.

- Usage: They are suitable for drilling softer rock formations, including clay, sandstone, soft limestone,andunconsolidated formations.

- Advantages: Drag bits are simple in design, cost-effective, and ideal for shallow drilling or softer rock formations.

- Applications: Drag bits are commonly used in water well drilling, environmental drilling, and some mining applications where softer

rock formations prevail.

Choosing the right rotary drill bit for rock drilling depends on factors such as the type of rock formation, drilling depth, drilling method

(e.g., rotary drilling, percussion drilling), and the desired drilling efficiency and performance. Each type of bit has its advantages and is

selected based on the specific requirements of the drilling operation.

Please contact with DrillMore's sales team for suitable bit slection.

WhatApp:https://wa.me/8619973325015

E-mail: [email protected]

Your email address will not be published. Required fields are marked with *