How To Choosing Rock Drill Tools

How To Choosing Rock Drill Tools

Step 1: Determine the Shank Configuration on Your Drill.

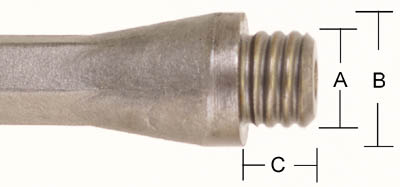

The first step in choosing the right steel and bits for your rock drill and application would be to determine the shank configuration on your drill.

There are only 3 common shank sizes. 7/8 x 3 ¼”, 7/8 x 4 ¼” and 1 x 4 ¼”. These measurements refer to the diameter of the hex steel (measured across the flats) and the length above the retaining collar. The larger sinker drills will usually run the larger steel but it is not uncommon to have a 55lb drill which is set up for a 7/8 x 3 ¼” shank. You must know which shank configuration you have prior to ordering your drill steel.

Step 2: Determine the Drill and Bit Configuration for Your Rock Drill Shank

H Thread Steel and Bits:

H thread is probably the most commonly used contractors thread due to its versatility and availability. The male thread on the steel is about 1” diameter and about 3/4” long. The steel is typically stocked from 12” to 120” long in all 3 shank configurations. The bits range from 1 3/8” up to 3” diameter in full carbide cross (most common), 1 3/8” to 2” in shallow carbide cross, 1 3/8” to 2 1/4” in button bit bits and 1 3/8” to 2 -5/8” diameter in an all steel bit.

H thread drill steel is usually made from a high carbon steel. It is usually forged, machined, and heat treated to have a wear resistant exterior while retaining a slightly softer core to handle and transfer impact energy. It is a shoulder drive steel which means the skirt of the bit tightens up to the forged/machined shoulder on the steel. The percussive energy is transferred though the steel and skirt of the bit to face – shattering the material in front of it.

While H thread steel is the most common contractors thread - it does have its inherent weaknesses. The shoulder drive dictates that the bit must remain tight against the shoulder of the steel. If it becomes loose from the shoulder – all of the drills forces are going very small threads on the bit and steel – and they will quickly fail. Keep constant down pressure and do not allow the drill to bounce in the hole and H thread should work very well in most hard rock drilling applications.

This bit has 4 large silver brazed carbide inserts that hold up extremely well in production hard rock drilling applications. They hold there gauge well and can be sharpened if they get too dull to be effective.

This bit has 4 large silver brazed carbide inserts that hold up extremely well in production hard rock drilling applications. They hold there gauge well and can be sharpened if they get too dull to be effective.

The economy bit costs a little less than the Full Carbide bit but has a fraction of the tungsten carbide insert. They can sometimes be more “economical” in some situations. (small jobs, very abrasive material, drilling in conditions prone to bit failures)

The economy bit costs a little less than the Full Carbide bit but has a fraction of the tungsten carbide insert. They can sometimes be more “economical” in some situations. (small jobs, very abrasive material, drilling in conditions prone to bit failures)

The button bit costs a little more than the Full Carbide cross bit. It has multiple carbide buttons pressed into the face of the bit. Larger hand drills can deliver enough impact energy to make these bits far superior to a cross bit in speed and longevity in the right conditions.

The button bit costs a little more than the Full Carbide cross bit. It has multiple carbide buttons pressed into the face of the bit. Larger hand drills can deliver enough impact energy to make these bits far superior to a cross bit in speed and longevity in the right conditions.

These cross bits are forged and hardened and are the least expensive options. Without the carbide component you can expect a relatively short lifespan especially in abrasive conditions.

These cross bits are forged and hardened and are the least expensive options. Without the carbide component you can expect a relatively short lifespan especially in abrasive conditions.

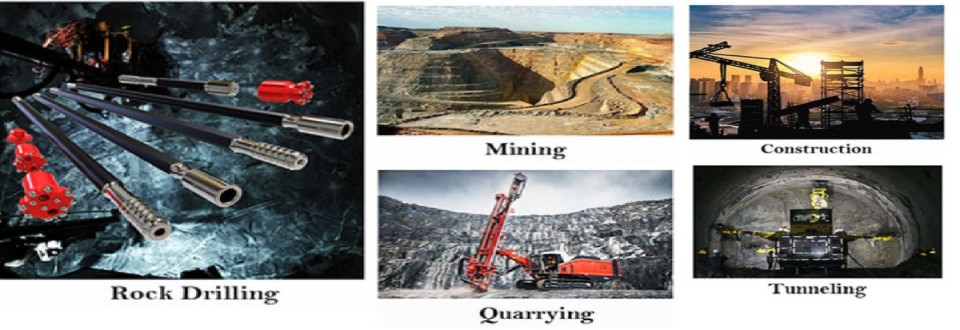

Tapered drill steel was/is primarily used in underground mining on jackleg drills. 12 degree taper is more prevalent in Canada and 11 degree is more prevalent in the US and Central America. The female tapered bit pushes on to the male tapered drill steel. Once mated – they can be separated by means of a bit knocker when the bit is worn out.

Some contractors have adopted it - as the steel is produced in larger volumes and is easier to manufacture therefore it can be less expensive. However, it was made for production mining and is limited in scope. The drill steels normal shank configuration is 7/8 x 4 ¼ and the range of bits is limited. Failure to maintain steady down pressure may result in losing the bit in the hole.

Rope threaded steel and bits:

100 rope (1” rope, R25) and 125 rope (1 ¼”rope, R32) are used extensively in underground production mining applications. Many contractors have turned to this type of steel to deliver a longer life, especially in more demanding conditions or when consistently drilling 2 ½” plus diameter holes. The drill steel is normally carburized which is a process of infusing the steel with carbon elements in a furnace. This gives the steel an extremely hard casing while maintaining a lower hardness inside to transfer the impact shockwave. The thread is larger/longer and will bottom out inside the rock bit. This combination is more forgiving in tough drilling conditions. Crowder Supply manufactures a large variety of steel and bit adaptors for larger track drills but it is seldom necessary to move beyond these two threads with hand drills.

Rope thread steels also give you the ability to run drill strings by using extension steels. This gives you the option to drill a deeper hole or to drill longer holes in confined spaces.

Please let us know if we can help with your drilling industrial [email protected]

Your email address will not be published. Required fields are marked with *