Different Types of Tricone Bit Bearings

Different Types of Tricone Bit Bearings

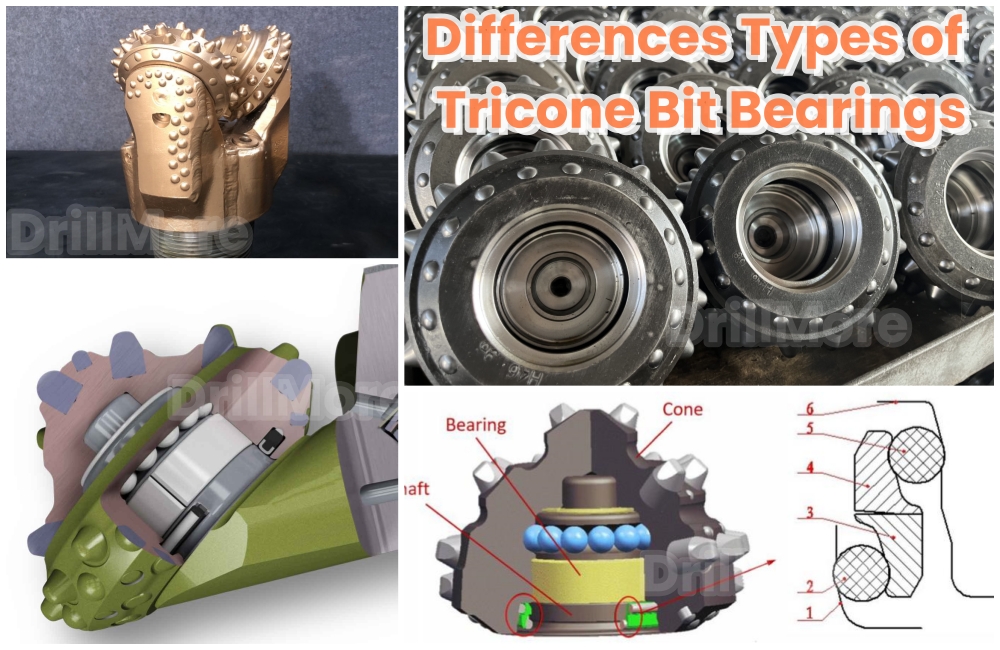

Tricone drill bits are essential tools in the drilling industry, used for drilling through various types of rock formations. The efficiency and lifespan of these bits are heavily influenced by the type of bearings they use. Here are four common types of tricone drill bit bearings and an explanation of how they work:

1. Open Bearing (Non-Sealed Bearing)

How They Work?

Open bearings, also known as non-sealed bearings, rely on the circulation of drilling fluid (mud) to lubricate and cool the bearing surfaces. The drilling fluid enters the bit through the nozzles and flows into the bearing area, providing lubrication and carrying away debris and heat generated during drilling.

Advantages

- Cost-Effective: Open bearings are generally less expensive to manufacture and maintain.

- Cooling: The continuous flow of drilling fluid helps to keep the bearing surfaces cool.

Disadvantages

- Contamination: The bearings are exposed to drilling debris, which can cause wear and tear.

- Shorter Lifespan: Due to contamination and less effective lubrication, open bearings typically have a shorter lifespan.

2. Sealed Roller Bearings

How They Work

Sealed roller bearings are enclosed with a seal to keep out drilling debris and retain lubricant within the bearing assembly. The seal can be made from rubber, metal, or a combination of both. These bearings are lubricated with grease or oil, which is sealed inside the bearing assembly.

Advantages

- Longer Lifespan: The seal protects the bearings from contamination, reducing wear and extending their lifespan.

- Improved Lubrication: The lubricant inside the sealed bearing provides continuous lubrication, reducing friction and heat.

Disadvantages

- Cost: Sealed bearings are more expensive than open bearings due to the additional sealing components and more complex design.

- Heat Buildup: Without the continuous flow of drilling fluid, there is a risk of heat buildup, although this is mitigated by the internal lubricant.

3. Sealed Journal Bearings

How They Work

Sealed journal bearings are similar to sealed roller bearings but use a journal design, where the bearing surfaces are in direct contact with the journal shaft. These bearings are also sealed to keep out debris and retain lubricant. The lubricant used is typically grease, which is pre-packed and sealed within the bearing assembly.

Advantages

- High Load Capacity: Journal bearings can support higher loads compared to roller bearings.

- Longer Lifespan: The sealed design protects the bearing surfaces from contamination, extending their lifespan.

Disadvantages

- Friction: Journal bearings have more surface contact than roller bearings, which can lead to higher friction.

- Heat Management: Like sealed roller bearings, heat buildup can be an issue if not properly managed.

4. Air-Cooled Bearings

How They Work

Air-cooled bearings use compressed air instead of drilling fluid to cool and lubricate the bearing surfaces. The compressed air is directed into the bearing assembly, carrying away heat and debris. This type of bearing is typically used in air drilling operations, where drilling fluid is not available, most apply in mining and quarrying.

Advantages

- Clean Operation: Air-cooled bearings are ideal for drilling in dry conditions or where drilling fluid is not practical.

- Reduced Contamination: The use of compressed air reduces the risk of contamination compared to fluid-lubricated bearings.

Disadvantages

- Limited Cooling: Air is less effective at cooling compared to drilling fluid, which can limit the operational lifespan of the bearings.

- Specialized Equipment: Air-cooled bearings require additional equipment for air supply and management.

Understanding the differences between these types of tricone drill bit bearings is crucial for selecting the right bit for specific drilling conditions. Each type of bearing has its own set of advantages and disadvantages, which should be carefully considered based on the specific requirements of the drilling project. By selecting the appropriate bearing type, drilling operations can achieve optimal performance, efficiency, and cost-effectiveness.

Check out with DrillMore sales team to determine which bearing type of tricone bit would be best for you!

WhatsApp: https://wa.me/8619973325015

E-mail: [email protected]

Web: www.drill-more.com

Your email address will not be published. Required fields are marked with *