Concentric Casing Overburden Drilling System With Ring Bit

Use concentric Casing System can drill complex formation (loose, unconsolidated material such as soil, clay, silt, sand, gravel and boulders) very well. DrillMore provide the whole product range the smallest being for 114 mm (4 1/2") casing and largest size available for 1220 mm (48") casing.

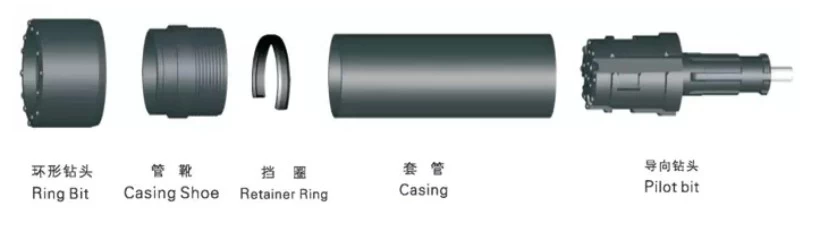

Concentric Casing Components: pilot bit, casing, retainer ring, casing shoe, ring bit.

Structural Advantages of Concentric Casing System:

1. Straightness: ensures the straightness of borehole in different topographic and geological conditions.

2. Adaptability: ensures penetration efficiency in complex topographic and geological conditions, such as gravel and landfill of construction refuse.

Lower torque: the system torque is less than eccentric casing system.

3. Easy to unlock an re-rock: easy to re-rock after unlock.

4. Drilling at any angle: concentric casing system can drill under horizontal, vertical and inclined conditions.

5. Environmental: better than eccentric casing system, because of its advantages of drilling smoothly, small vibration and low noise, it is more suitable for construction in urban areas.

| Working principle of Concentric Casing System | |||

|  |  |  |

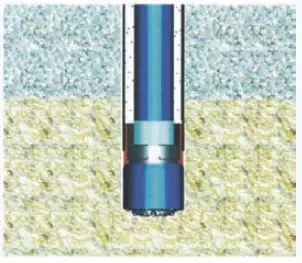

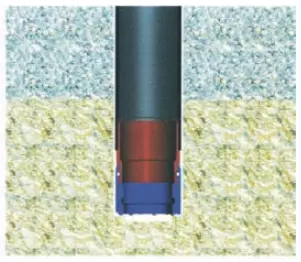

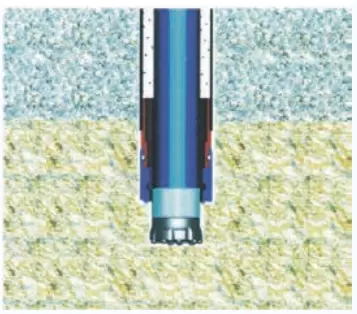

| Ring bit and casing shoe assembly is welded to casing prior to drilling. Lock the assembly into pilot bit with hammer. The pilot bit's shoulder engages the shoulder of the casing shoe. | Hammer's percussive energy is transferred through the pilot and ring bits, crushing rock . Part of impact energy advances casing. | On completion of drilling and casing , the drill string with pilot bit is retrieved by a slight reverse rotation to unlock the bayonet coupling . The ring bit stays in the hole , and can be recovered only if the casing is retrieved. | If drilling continues to the desired depth in the bedrock is required, using a conventional DTH drilling bit. |

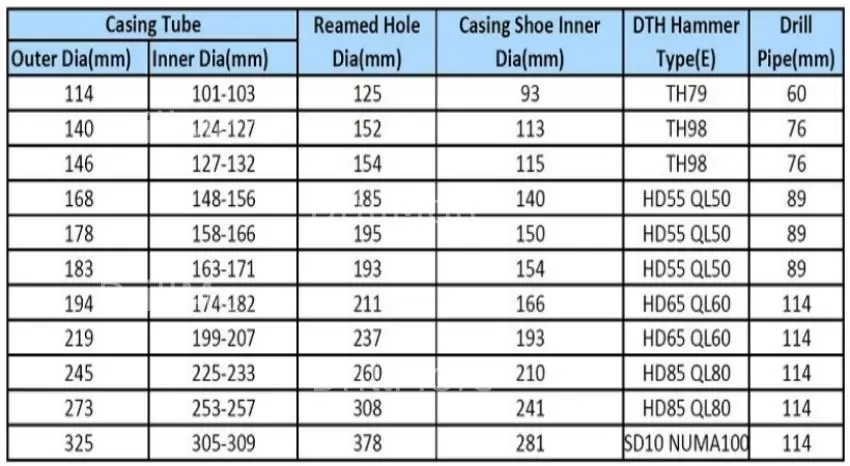

Following is regular model of DrillMore's Concentric Casing System:

How to place an order?

1. Casing Tube Out Diameter & Inner Diameter

2. Ring Bit Diameter

3. Hammer Shank Style

4. Pilot Bit Diameter

DrillMore Rock Tools

DrillMore is dedicated to the success of our customers by suppling drilling bits to each application. We offers our customers in the drilling industry many options, if you do not find the bit you are looking for please contact our sales team at following to find the correct bit for your application.

Head Office: XINHUAXI ROAD 999, LUSONG DISTRICT, ZHUZHOU HUNAN CHINA

Telephone: +86 199 7332 5015

WhatsApp: https://wa.me/8619973325015

Email: [email protected]

Call us now!

We are here to help.

Your email address will not be published. Required fields are marked with *