Three Types Of Rock Drilling

Three Types Of Rock Drilling

There are three methods of rock drilling — Rotary drilling, DTH (down the hole) drilling and Top hammer drilling. These three ways are suitable for different mining and well drilling operations, and the wrong choice will cause huge loss.

First of all, we have to know the working principles of them.

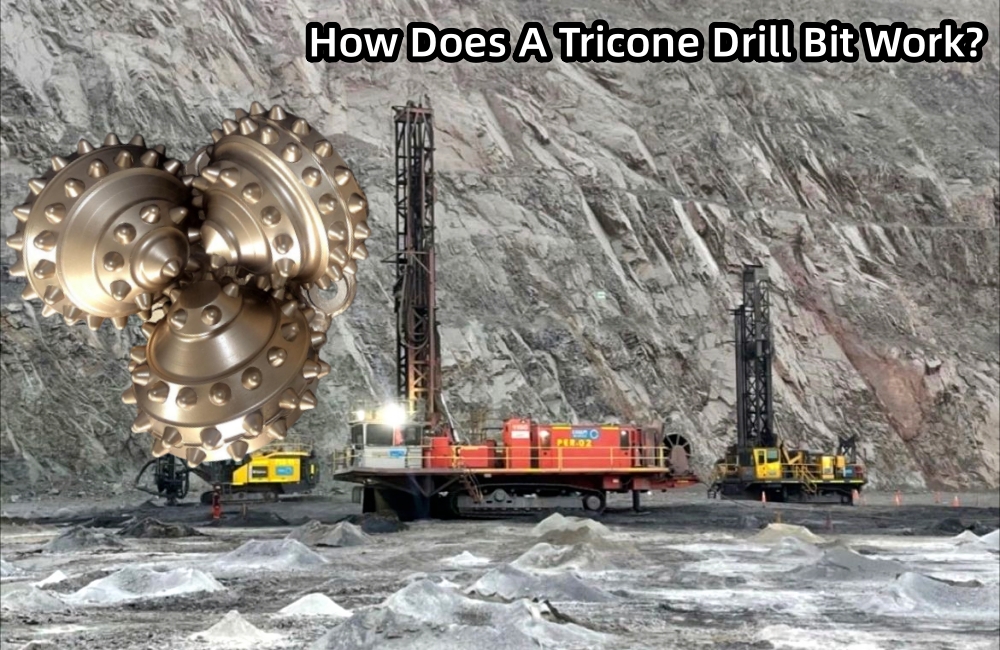

In rotary drilling, the rig provides enough shaft pressure and rotary torque. The bit drills and rotates on the rock at the same time, which exerts both static and dynamic impact pressure on the rock. The bits rotate and grind continuously in the bottom of the hole to make the rock to fracture. Compressed air under a certain pressure and flow rate are sprayed from the nozzle through the inner of the drill pipe, to make the slag continuously blown from the bottom of the hole along the annular space between the drill pipe and the whole wall to the outside.

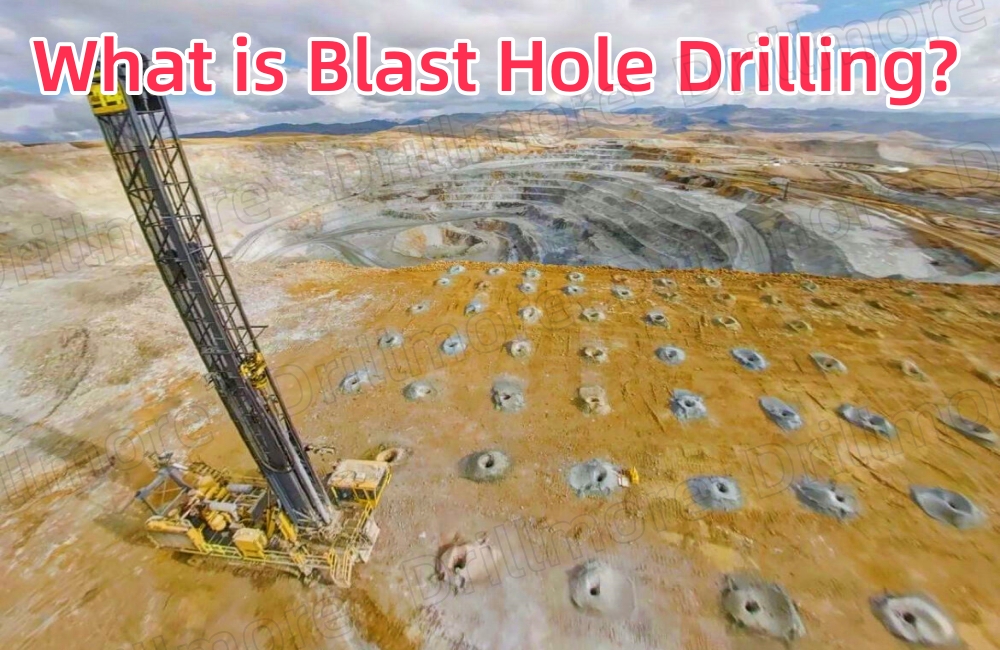

Down-the-hole drilling is to drive the hammer which behind the drill bit by compressed air via the drill pipe. The piston strikes the bit directly, while the hammer external cylinder gives straight and stable guidance of the drill bit. This makes the impact of energy is not lost in joints and allowing for much deeper percussion drilling.

Furthermore, the impact force acts on the rock at the bottom of the hole, which is more efficient, and straighter than other methods of the drilling operation.

And DTH is more suitable for the big hole of hard rock drilling, special for rock hardness over 200Mpa. However, for the rock below 200 MPa, it will not only energy waste, but also in low drilling efficiency, and serious wear to the drill bit. It’s because while the piston of the hammer strike, the soft rock cannot absorb the impact completely, which seriously lower the efficiency of drilling and slagging.

The percussive force of the top hammer drilling produced by the piston of the pump in the hydraulic drilling rig, it is transmitted to the drill bit via shank adaptor and drill pipe.

This is the difference between DTH drilling. Meanwhile, the percussion system drives the drilling system rotation. When the stress wave reaches the drill bit, the energy is transmitted to the rock in the form of bit penetration. The combination of these functions enables drilling holes into the hard rock, and the air compressor only performs dust removal and slagging in top hammer drilling.

The combination of these functions enables drilling holes into the hard rock, and the air compressor only performs dust removal and slagging in top hammer drilling.

Impact energy multiplied by impact frequency together creates the percussive output of the drifter. However, usually, top hammer drilling used for hole diameter maximum 127mm, and hole depth less than 20M, which in high efficiency.

Your email address will not be published. Required fields are marked with *