How to Address Tooth Chipping Issues in Tricone Drill Bits

How to Address Tooth Chipping Issues in Tricone Drill Bits

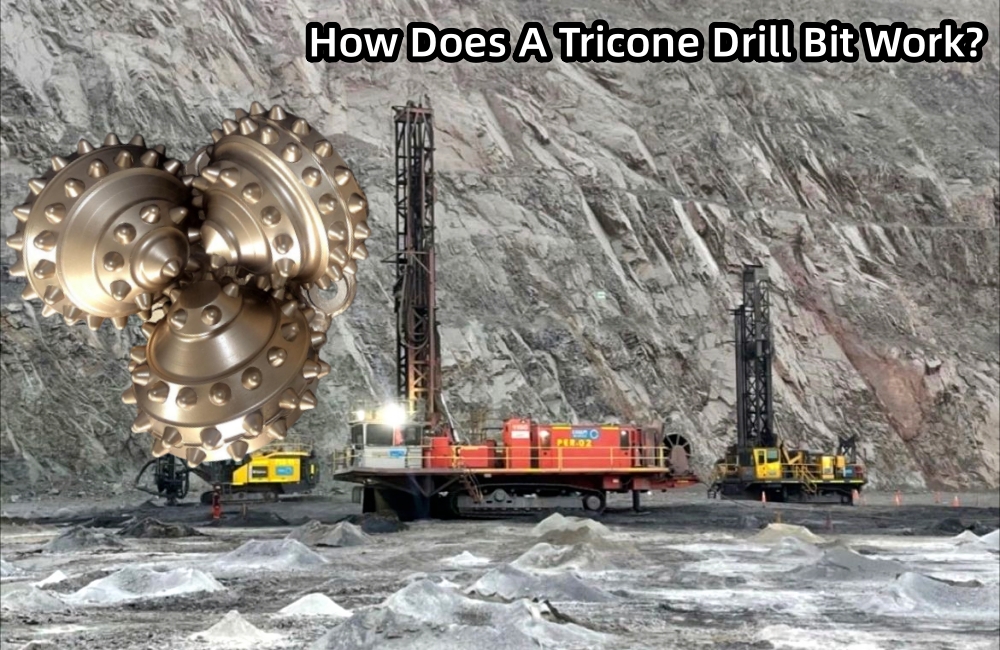

Tricone bit is an essential drilling tool in oil and gas exploration, mineral extraction, and various engineering projects. However, as drilling depth and complexity increase, the problem of tooth chipping on tricone bits has garnered significant attention within the industry. As a leader in manufacture of rock drilling tools field, DrillMore is committed to helping customers overcome these challenges, enhance drilling efficiency and reliability through continuous innovation and high-quality products.

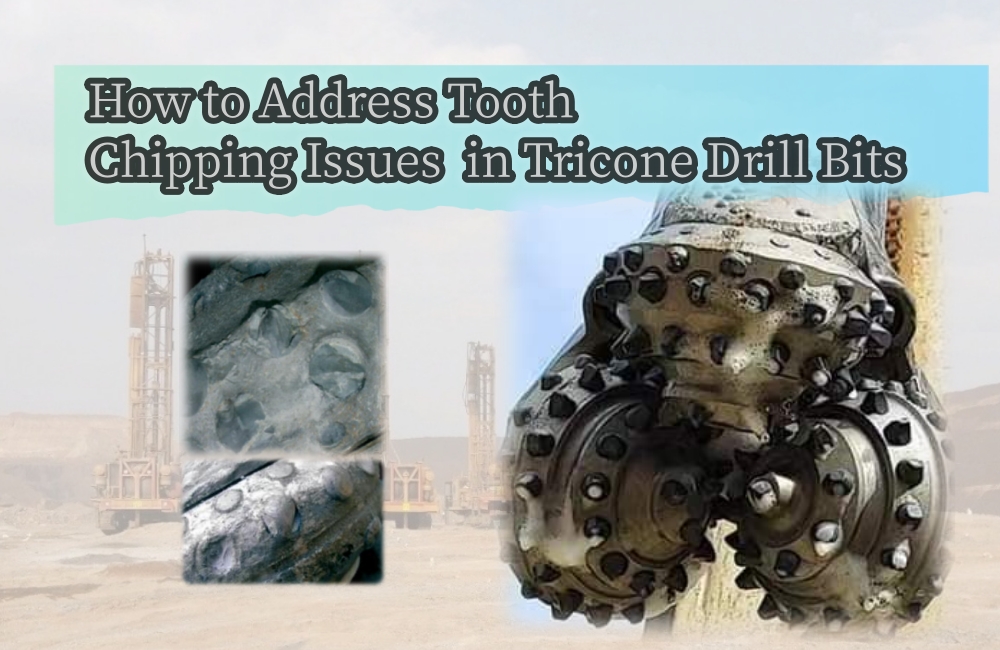

Causes of Tooth Chipping

1. Excessive Drilling Pressure

Excessive drilling pressure can exceed the design specifications of the drill bit, resulting in tooth chipping under high stress. This issue is particularly prevalent in hard or non-homogeneous formations, where excessive drilling pressure can lead to accelerated wear of the teeth.

2. Drilling in Fractured Rock Formations

Fractured rock formations often contain irregular fissures and hard particles that exert uneven loads on the teeth, leading to localized stress concentrations and subsequent chipping. Such challenging geological conditions demand drill bits with enhanced wear resistance.

3. Improper Tungsten Carbide Teeth Selection

Selecting an teeth material with insufficient hardness or abrasion resistance for complex geological conditions can result in rapid wear and chipping of the teeth, negatively impacting drilling efficiency and reducing bit life.

4. Interference Between Roller Cones

Improper design of the clearance between the roller cones can cause mutual interference, increasing the risk of tooth chipping. This not only diminishes drill bit performance but also adversely affects overall drilling operations.

As an industry-leading supplier of rock drilling tools, DrillMore understands the challenges our customers face and offers a range of superior solutions backed by years of technological innovation and expertise.

1. Adjustment of Operational Practices and Reduction of Drilling Pressure

DrillMore's tricone bits are precision-engineered to perform optimally across a variety of drilling conditions. DrillMore recommends that customers adjust drilling pressure according to specific formation conditions, and provides detailed operational guidelines to help extend the lifespan of drill bits without sacrificing drilling efficiency.

2. Application of High-Performance Wear-Resistant Tungsten Carbide Teeth

For fractured rock formations and highly abrasive geological conditions, DrillMore has developed tricone bits using advanced wear-resistant materials. These materials have undergone rigorous laboratory testing and field trials, significantly enhancing the durability and stability of the drill bits. No matter how extreme the conditions, DrillMore's bits help customers tackle challenges while minimizing the risk of tooth chipping.

3. Precision Manufacturing and Optimization of Roller Cone Designs

DrillMore employs state-of-the-art CNC technology and strict quality control measures in the design and manufacture of its drill bits, ensuring precise clearance between the cones. DrillMore's engineering team continuously refines the design to reduce the likelihood of cone interference, thereby improving overall drill bit performance. This precise design not only boosts drilling efficiency but also reduces the risk of tooth failure.

While tooth chipping presents a significant challenge in complex geological conditions and difficult drilling tasks, it is not an inevitable problem. DrillMore not only offers high-quality drilling tools but also provides comprehensive technical support and operational advice to help you maximize drilling efficiency, extend equipment life, and reduce operational costs.

Whatever your drilling challenges may be, DrillMore is your trusted partner. DrillMore will continue to innovate and optimize products, helping our customers achieve greater success.

Your email address will not be published. Required fields are marked with *