Working Theory Of Tricone Bits

Working Theory Of Tricone Bits

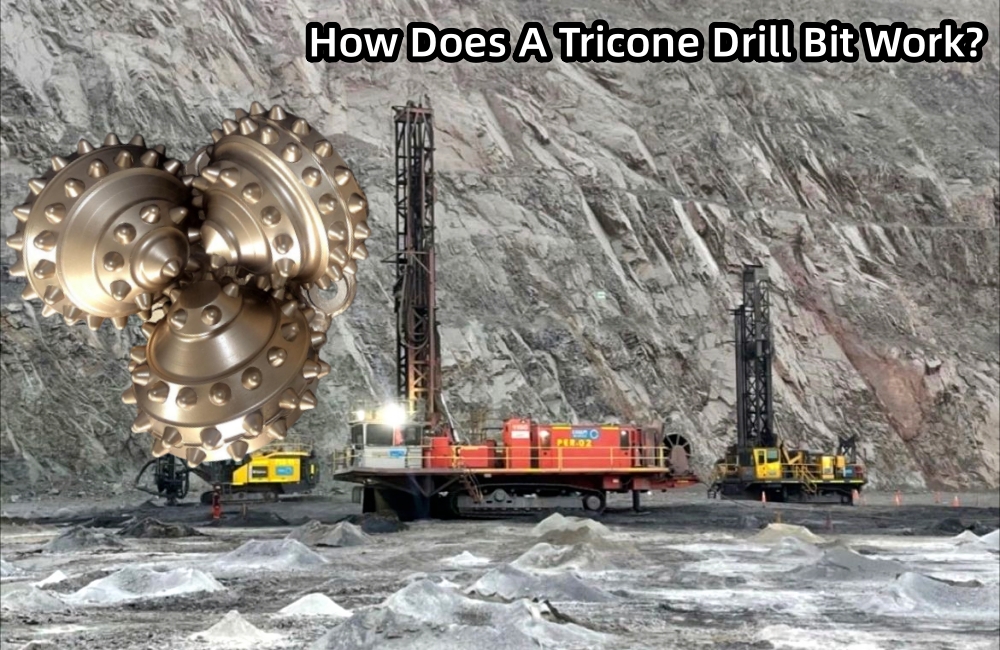

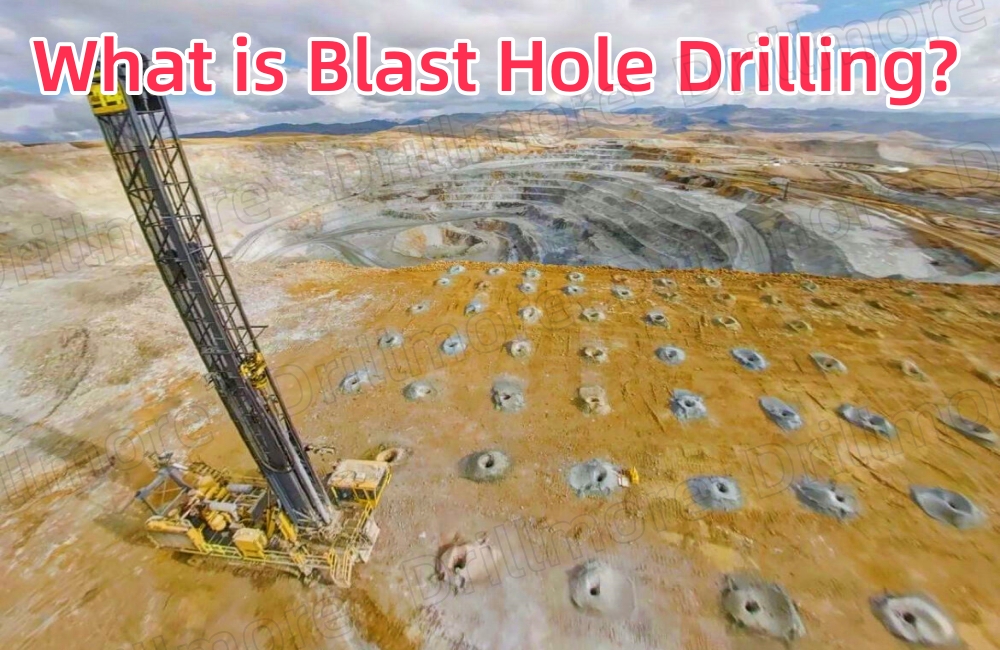

Tricone bit is one of the main tools for blast hole and well drilling. It's life and performance has a great influence on the drilling quality, speed and cost of drilling project.

The rock breakage by the tricone bit which used in mine is working with both the impact of teeth and the shear caused by slippage of the teeth, which bring high rock breaking efficiency and the low operation cost.

The tricone bits developed and manufactured by our company are widely used for open pit mining,gas/oil/water well drilling, quarrying, foundation clearing and so on.

Tricone bit is connected with the drill pipe and rotates along with it, and drive cones which pressed on the rock together. Each cone rotates round the axis of its leg and simultaneously revolves around the bit center. The tungsten carbide inserts or steel teeth on the cone shell cause the formation to spall under the drill weight and the impact load from cone rotation, the cuttings will be discharged out of hole by compression air or with agent such as foam.

Each carbide insert or steel teeth pressed into the rock once with a certain depth of spall-pit on the rock. This limited depth of spalling seems to be approximately equal to the penetration depth per rotation of the bit. The teeth shape, the groove width and the crest length are all critical factors for rock breaking. With a comprehensive consideration of those factors such as the weight, RPM and air volume required for removing cutting from the hole, the designers may reasonably manipulate the interrelationships among them and make the bits gain highly efficient penetration rate and longer service life and achieve optimum economic results.

Your email address will not be published. Required fields are marked with *